Payment Type:T/T,Paypal,Western Union

Incoterm:FOB,CFR,CIF,EXW,FCA,CPT,CIP

Min. Order:500 Piece/Pieces

Transportation:Ocean,Land,Air

Model No.: Customized

Brand: Jinghui ceramics

Packaging: Export carton

Productivity: 100,000 sets/month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 500,000 sets/month

Certificate: RoHS

HS Code: 8547100000

Payment Type: T/T,Paypal,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

1. Various complicated design production capability with tighten tolerance, precise dimensions

2. Excellent wear and abrasive resistance, much higher 276 times than stainless steel

3. Much higher density than most of technical and advanced ceramics, over than 6 g/cm3

4. Exceptional high hardness, over than 1300 MPa for Vicker hardness, it leads to high wear resistance

5. Can withstand higher temperatures up to 2400° under vacuum or reduced atmospheres

6. Low thermal conductivity, less than 3 W/m.k at room temperature, so it can couple with metal well

7. Exceptional fracture toughness than almost advance ceramics, reaches up to 8 Mpa m1/2

9. Chemical inertness which can withstand most of acids and alkali, aging resistance and not rust forever

10. Resistance to molten metals and avoid any metal residual on surface due to an extraordinary melting point

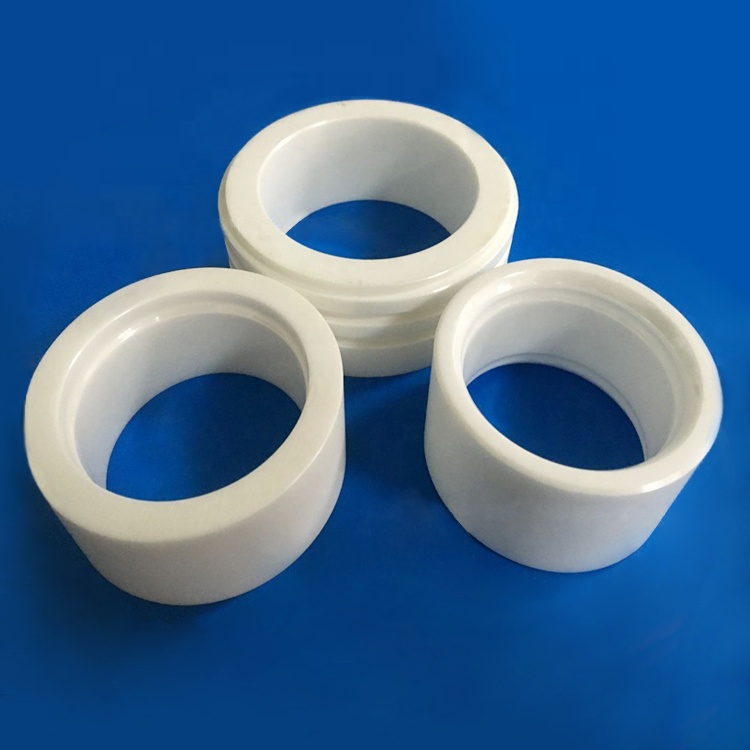

1. Raw material options: zirconium oxide, aluminum oxide, silicon nitride, silicon carbide

2. Forming methods: Dry pressing, hot pressing, ISO pressing, ceramic injection molding, extrusion

3. Typical designs: round tube, square tube, rectangular tube, slotted tube, half tube, flanged tube

4. Dimensional capability: OD is range from 1 mm to 300 mm, length from 0.5mm to 800 mm

5. Secondary processing : Fine grinding, Drilling, Laser cutting, CNC machining, lapping

6. Accuracy capability: The tolerance of OD can be ± 0.001 mm, ID ± 0.005 mm, length ± 0.10 mm

7. Surface treatment : polishing with diamond - like surface, glazing, metallzing for ceramic to metal jointing

8. Surface quality: Free of cracks, foreign contamination, mirror surface better than Ra 0.1

With our state-of-the-art and comprehensive in-housing precision machines, we could deal with different level accuracy ceramic tubes per customers' need, also the surface finish, like polishing, glazing and metalizing for ceramic to metal brazing can be done at home.

Additionally, we also manufacture Alumina Ceramic Tube, silicon carbide tube, silicon nitride tube in flange, threaded, half tube or various of special design.Whatever, it's a prototyping case or high volume demand, we could help your business.

Remark: we have been supplying variety of customized Zirconia Ceramic Tube per customers' specification,

real samples with low MOQ requirement.

We have in-housing comprehensive manufacturing types of equipment, including forming, sintering, CNC machining,

precision grinding, laser cutting and so on, it helps us to control the quality very well, also it greatly benefits cost control.

Q 1: Is it available to provide customized products?

A: We offer custom-made demand service as per different grade materials, dimensions, and designs.

Q 2. Are you a factory or trading company?

A: We are a direct manufacturer with own complete manufacturing machines from forming to sintering.

Q 3: Do you send a sample to check?

A: Sure, the standard design sample in stock will be free and freight collect.

We also support trail/sample order with very low-level quality for R&D or prototyping needs

Q 4: When can I get the price?

A: We regularly quote within 24 hours after we get your inquiry. If you are in urgent need of getting the price.

Please call us or tell us in your email so that we will proceed with your inquiry as a priority.

Q 5: How to ensure quality?

A: IQC, IPQC, QA, OQC are strictly performed from incoming material to inspection of finished products.

CKP and AQL value are introduced in the processing line, Fully cosmetic inspection will be carried out.

Q 6: What other products are you dealing with?

A: We focus on a variety of Ceramic Substrate, Metallized ceramics, ceramic seal and Textile Ceramics besides zirconia ceramic tube.