Min. Order:100 Piece/Pieces

Transportation:Ocean,Land,Air,Express

Port:Shenzhen Port,HongKong Port,Shanghai Port

$7.5200-499Bag/Bags

$7500-999Bag/Bags

$61000-4999Bag/Bags

$5≥5000Bag/Bags

Model No.: Customized

Brand: Jinghui ceramics

Place Of Origin: China

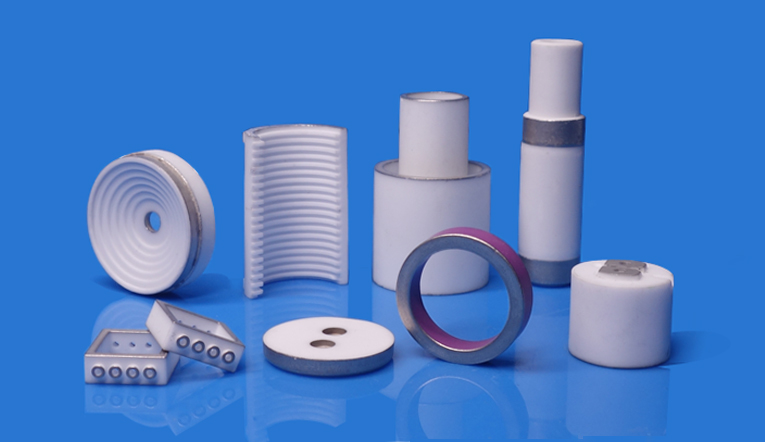

Species: Ceramic Parts

Application: Industrial Ceramic

Material: Alumina Ceramic

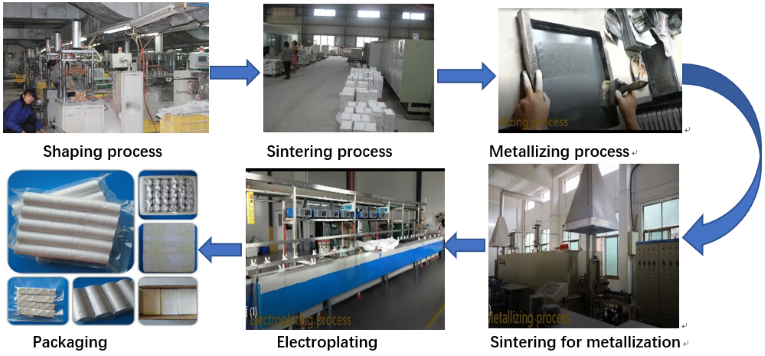

Processing Service: Moulding

Precision Process: Fine Grinding, Cnc Machining

Color: White, Pink Optional

Metallization Type: Mo/Mn ,W Optional

Coating Type: Nickle Plating

Thickness Of Metallization: 20~40um

Thickness Of Plating: Thin Or Thick Film Avaiable

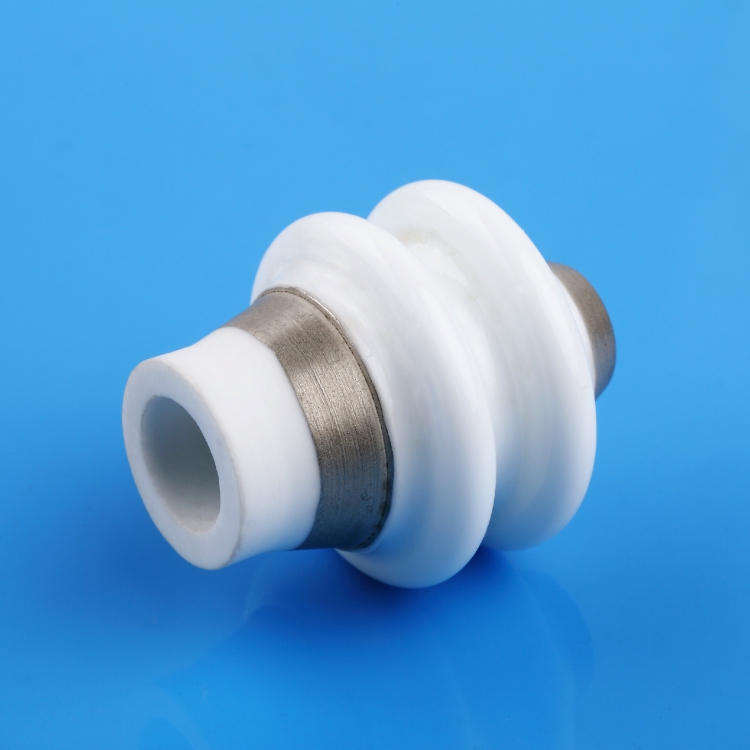

Feature: High Bonding Strength With Ideal Hermercity

Application: Ceramic To Metal Jointing Technology

Type: Metallized Ceramic Insulator

Product Name: High Current Vacuum Ceramic Component

Packaging: Vacumm packaging with export carton

Productivity: 50,000pcs/month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 200,000pcs/month

Certificate: RoHS

HS Code: 8547100000

Port: Shenzhen Port,HongKong Port,Shanghai Port

To achieve the ceramics to the metals joining application, a metal coating will be applied on the specific surface of the ceramic component, a metal film on ceramic insulator will be formed after high-temperature fire, afterwards, the ceramic to the metal, the ceramic to the ceramic can be brazed together. We provide different type metallization with metal coating via banding, screen printing, brushing, spraying, like Mo/Mn with nickel plating, Tungsten(W) with gold plating, silver plating.

These metalized ceramic insulator are commonly made from Alumina Ceramic with min. 95% purity. They are formed via dry pressed,Isostatic pressed , ceramic injection molding or hot pressed. With their exceptional high insulation, anti-high voltage and high current properties, all of them play a very important role in vacuum-based devices.

Besides Metallized ceramics, we offer other wide of ceramic parts, like Zirconia Ceramic Components, Ceramic Seals , Thermostat Ceramics, Textile Ceramics, various of the Advanced Ceramic Plate and Ceramic Tubes and so on.

| Leak Rate | ≤1x10-11Pa.m3/s | Metal Layer Tensile Strength | ≥150Mpa |

| Volume Resistivity | ≥108Ω•cm | Coefficient of Thermal Expansion | (6.5 ~ 8.0) × 10-6 /°C |

| Insulation Strength | ≥20kV/mm (D•C) | Dielectric Constant | 9~10(1MHz, 20°C) |

| Cosmetic Quality:1. No cracks, no bubbles; 2. Evenly distributed glaze; 3. No contamination | |||

It's widely used in electronics, high vacuum devices, medical technology and sensor technology, military, aerospace and so on.

We have in-house complete comprehensive manufacturing equipment from shaping to electroplating,also with various complex shaping production capability.Whatever, it's a prototyping need or cost down project, we believe we can help your business.

Q 1. Is it available to provide customize products?

A: We always support custom-made demand as per different dimensions, design and metallization and plating.

Q 2. When can I get the price?

A: We regularly quote within 24 hours after we get your inquiry.

Q 3. How long does the whole procedure being worked out?

A: After you place an order, the manufacturing time is about 25 working days.

Q 4. What about transportation and delivery date?

A: Normally we use Int`l express by our forwarder, or with client`s account number. It is about 3~5 working days.

Q 5. How to ensure quality?

A: The dimension out of any batch will be carried out sampling inspection per International AQL standard. 100% cosmetic inspection will be done.