Payment Type:T/T,Paypal,Western Union

Incoterm:FOB,CFR,CIF,EXW,FCA,CPT,CIP

Min. Order:10 Piece/Pieces

Transportation:Ocean,Land,Air

Port:Shenzhen,HongKong,Shanghai

Model No.: Customized

Brand: Jinghui ceramics

Packaging: Vacumm packaging with export carton

Productivity: 500,000pcs/month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 2,000,000pcs/month

Certificate: RoHS

HS Code: 8547100000

Port: Shenzhen,HongKong,Shanghai

Payment Type: T/T,Paypal,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

1. Readily accepts Mo/Mn or W metalization for high-temperature brazing of metal to ceramic assemblies

2. Excellent bonding strength over 150 MPa and with ideal leakage rate less than ≤1×10-11 Pa•m3 / s

3. Dense, non-porous ceramic body free of foreign substance and ideal vacuum air tightness

4. High volume resistivity with high insulation strength greater than 18KV/mm (D.C) at least

5. Low coefficient of expansion between 5 to 8 ×10 -6 /℃ under room temperature to 800℃

6. Resists chemical attack which withstand most of strong acid and alkali harsh environment

7. Anti - aging, it's free of rust forever even if the ceramic body expose into air in a long term

8. Fire - resistant & heat - resistance, and high temperature resistance up to 1650 ℃

1. Raw material available: alumina (al2o3), zirconia (ZrO2), beryllia oxide (BeO) and aluminum nitride (AlN)

2. Forming methods: Dry pressing, hot pressing, isostatic pressing, ceramic injection molding and so on

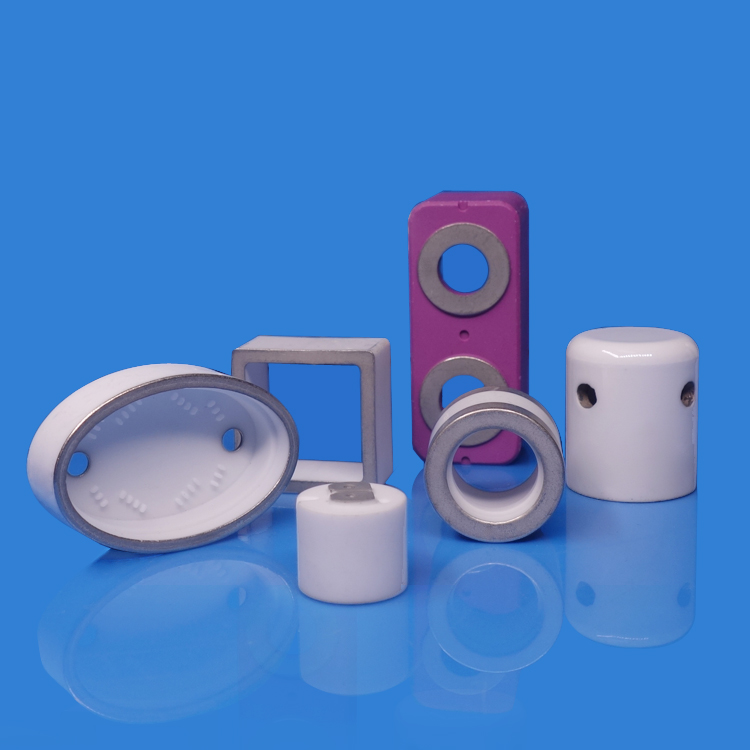

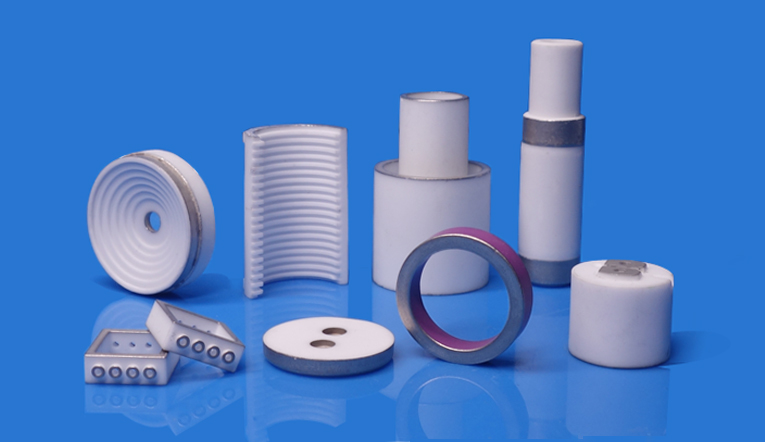

3. Types of ceramic components: ceramic tube, ceramic insulator, Ceramic Substrate, ceramic rings, ceramic cylinder

4. Dimensions capability: Outer diameter can up to be 800 mm, length can over 1000 mm

5. Tolerance : outer diameter can be 0.005 mm, inner diameter can be 0.01 mm, length can be 0.01 mm

6. Other technical parameters: flatness to be 0.005 mm, roundness to be 0.01 mm, parallelism to be 0.01mm

7. Typical metallization : ceramic body + Mo / Mn plating, ceramic body + Mo / Mn + Ni plating

We offer a selection of different grades metalized ceramic components, they are made out of 95%, 99% aluminum oxide ceramics, also zirconium oxide ceramics or beryllia oxide ceramics . These metallized ceramic components are widely used in the electrical and electronic, high vacuum applications, like electron tubes, power grid tubes, vacuum thyristors, gas triode and so on.

Except for Metallized ceramics, we manufacturer many other advanced ceramic parts, like ceramic substrate, Ceramic Tubes, Ceramic Seals, Textile Ceramics and so on.

● Offering competitive price with reliable technical ceramic parts ● Support standard to custom made parts

● In-house state -of-the-art types of manufacturing equipment● Within 8 hours response with flexible delivery

● Over 15 years of OEM, ODM manufacturing experience with professional and skillful production & QA team

● Powerful R & D capability and support prototyping of new products to mass serial production of matured products

● Focus on providing cost - effective and optimized solutions ● Support flexible delivery and insist punctual delivery

● Customer can design their ideal precision to get desired fitting● Support very small batch or trial order to meet R&D needs

● Offer technical information consultation and information, provide reference market trends and information

We have a complete comprehensive of production equipment for metallized ceramics from shaping to electroplating.

It helps us to make the dimensional consistency very well. Also, helping us to offer a competitive price.

Q 1. Is it available to provide customize products?

A: We could support custom-made demand as per different dimensions, design and metallization and plating.

Q 2. When can I get the price?

A: We regularly quote within 24 hours after we get your inquiry.

Q 4. What about the transportation and delivery date?

A: Normally we use Int`l express by our forwarder, or with client`s account number. It is about 3~5 working days.

Q 5. How to ensure the quality?

A: The dimension out of any batch will be carried out sampling inspection per International AQL standard. 100% cosmetic inspection will be done.