Payment Type:L/C,T/T,Paypal,Money Gram,Western Union

Incoterm:FOB,CFR,CIF,EXW,FCA,CPT,CIP

Min. Order:100 Piece/Pieces

Transportation:Ocean,Land,Air

Port:Shenzhen Port,Hongkong Port

Model No.: Customized

Brand: Jinghui ceramics

Packaging: Vacumm packaging with export carton

Productivity: 50,000pcs/month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 200,000pcs/month

Certificate: RoHS

HS Code: 8547100000

Port: Shenzhen Port,Hongkong Port

Payment Type: L/C,T/T,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

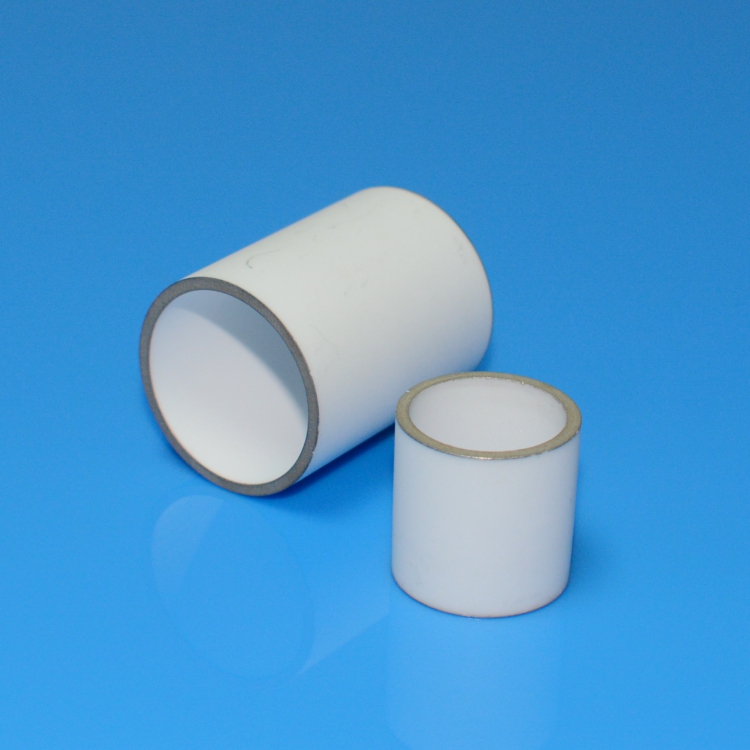

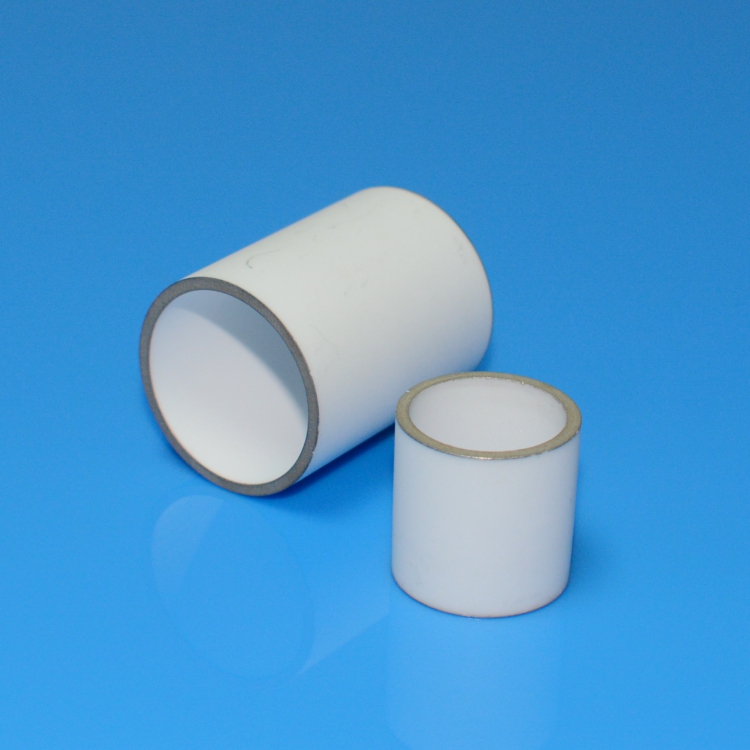

Alumina oxide ceramics to be a ideal raw material for metallized ceramic insulation tube as its high insulation resistance, great mechanical strength and electrical & electronic performance. It always work as ceramic insulator tube or ceramic insulating body in medium or high voltage/ currency vacuum interrupter devices.

As its special application, a metal layer plating at both ends is must, also the glazed surface is needed. The Vacuum Interrupter Ceramic Tube we manufacturer have a reliable brazing strength, ideal hermeticity.

Small part-size to large part-size is availability, the min. diameter can be 1mm, the largest diameter is up to 800mm. The typical plating as below:

1. Raw ceramic + Mo/Mn metallization 2. Raw ceramic + Mo/Mn metallization + Nickle plating

We are capable of offering high precision Metallized Ceramic Tube via variety of grinding, CNC machining, cutting processes. The finest tolerance can be +/-0.001 for length, +/-0.005 for inner and outer diameter. Prototyping to mass production is an advantage to us because of our own comprehensive production line.

We have a complete comprehensive of production equipment for Metallized ceramics from shaping to electroplating.

It helps us to make the dimensional consistency very well. Also, helping us to offer a competitive price.

Q 1. Is it available to provide customize products?

A: We could support custom-made demand as per different dimensions, design and metallization and plating.

Q 2. When can I get the price?

A: We regularly quote within 24 hours after we get your inquiry.

Q 4. What about the transportation and delivery date?

A: Normally we use Int`l express by our forwarder, or with client`s account number. It is about 3~5 working days.

Q 5. How to ensure the quality?

A: The dimension out of any batch will be carried out sampling inspection per International AQL standard. 100% cosmetic inspection will be done.