Min. Order:10 Piece/Pieces

Transportation:Ocean,Land,Air,Express

Port:Shenzhen Port,HongKong Port

$20-100 /Piece/Pieces

Model No.: Customized

Brand: Jinghui ceramics

Place Of Origin: China

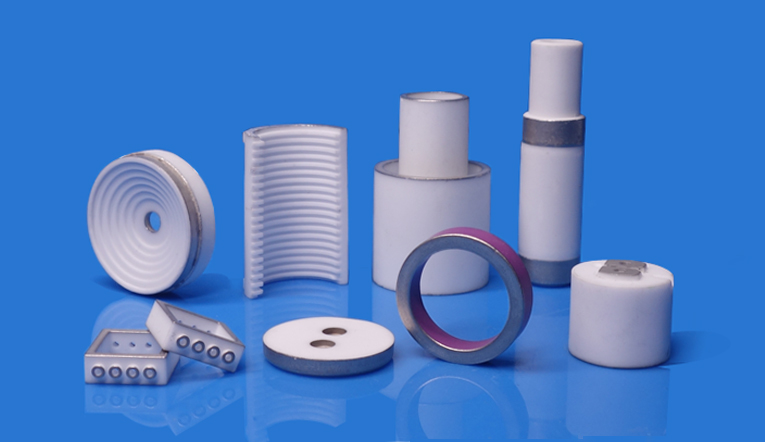

Species: Ceramic Parts

Application: Industrial Ceramic

Material: Alumina Ceramic

Processing Service: Moulding

Color: White, Pink Optional

Metallization Type: Mo/Mn ,W Optional

Coating Type: Nickle Plating

Thickness Of Metallization: 20~40um

Thickness Of Plating: Thin Or Thick Film Avaiable

Feature: High Bonding Strength With Ideal Hermercity

Material: Min. 95% Alumina

Precision Process: Fine Grinding

Type: Metallized Ceramic Housing

Application: Alumina Insulator For Metal-ceramic Transmitting T

Packaging: Vacumm packaging with export carton

Productivity: 50,000pcs/month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 200,000pcs/month

Certificate: RoHS

HS Code: 8547100000

Port: Shenzhen Port,HongKong Port

Jinghui supplies a great many of metallized ceramic insulators, all these Metallized ceramics are ideal for use in high vacuum, high current, high voltage and high pressure applications.

We provide metallised ceramics for surge arresters, gas discharge tube, power grid tube, RF window, vacuum interrupters, x-ray tubes.

Aluminum oxide is one of more regular engineering technical ceramic material, which can offer outstanding electrical insulation, excellent mechanical properties and resistant to chemical. They are often used as the ceramic body base of Metallized Ceramic Components. In addition, other fine ceramic material can be requested, like zirconia, beryllia.

We offer different grade dimensional accuracy of Metallized Ceramics as customers' desire with our in-housing secondary equipment.

Prime features of Metalized Ceramics:

●Readily accepts Mo/Mn or W metallizing for high temperature brazing of variety of metal to ceramic assemblies

●Excellent bonding strength with ideal leakage rate ........● Dense, non-porous and vacuum tight.............●High volume resistivity

●Low coefficient of expansion....................................................●Fire resistant and non-outgassing......................●Resists chemical attack

Our strength for Vacuum Ceramic Component

●Offering competitive price●Support standard to custom made item

●State of art secondary precision process●Quick response with flexible delivery●Prototyping to mass production capability

Customers' benefit

●Cost effective ● Flexible production schedule●Customer can design their ideal precision

●Support very small batch or trial order to meet R&D needs●Offer technical information consulation and support

We have a complete comprehensive of production equipment for metallized ceramics from shaping to electroplating.

It helps us to make the dimensional consistency very well. Also, helping us to offer a competitive price.

Q 1. Is it available to provide customize products?

A: We could support custom-made demand as per different dimensions, design and metallization and plating.

Q 2. When can I get the price?

A: We regularly quote within 24 hours after we get your inquiry.

Q 3. How long does the whole procedure being worked out?

A: After you place an order, the manufacturing time is about 25 working days.

Q 4. What about the transportation and delivery date?

A: Normally we use Int`l express by our forwarder, or with client`s account number. It is about 3~5 working days.

Q 5. How to ensure the quality?

A: The dimension out of any batch will be carried out sampling inspection per International AQL standard. 100% cosmetic inspection will done.