Payment Type:T/T,Paypal,Money Gram,Western Union

Incoterm:FOB,CIF,FCA

Min. Order:100 Set/Sets

Transportation:Ocean,Land,Air

Model No.: Standard or custom-made

Brand: Jinghui ceramics

Packaging: Export carton

Productivity: 1,000,000pcs/month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 2,000,000 pieces/month

Certificate: RoHS

HS Code: 8547100000

Payment Type: T/T,Paypal,Money Gram,Western Union

Incoterm: FOB,CIF,FCA

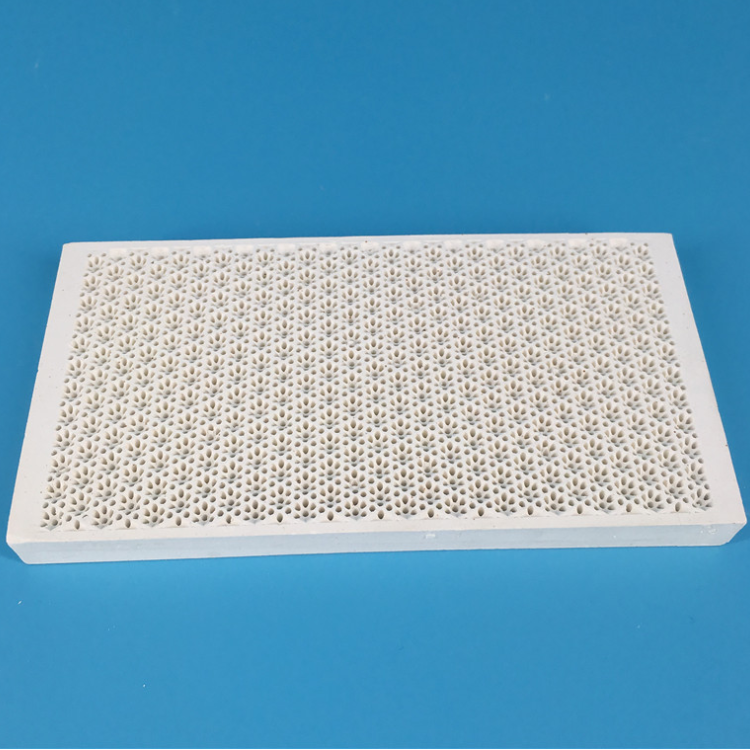

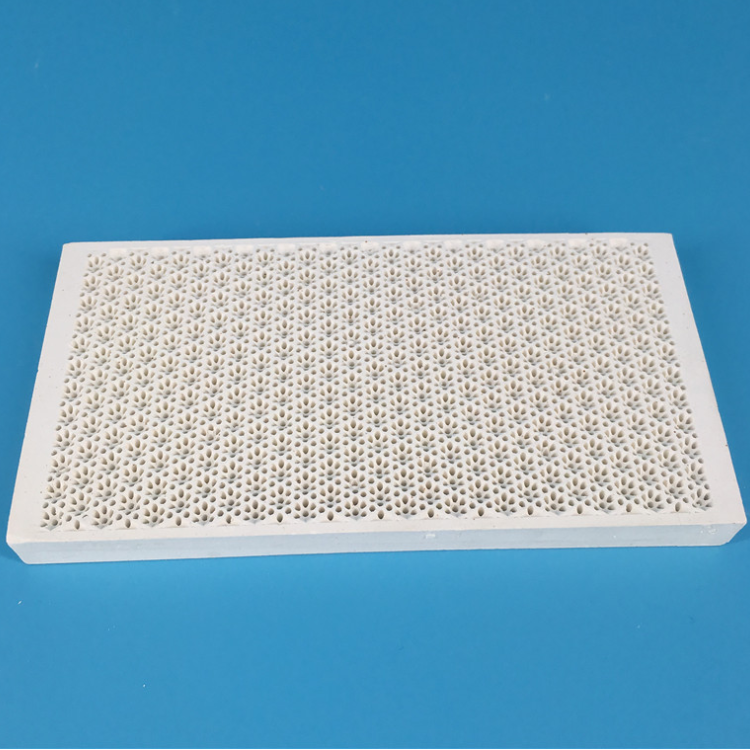

Cordierite honeycomb ceramic plates are widely used in energy-saving technologies for industrial thermal equipment, making industrial thermal equipment more efficient, reducing energy consumption, increasing production and improving quality. It is an important and effective means to solve energy and environmental problems. The cross-section holes of the honeycomb ceramic plate mainly have two kinds of hole structures of a square shape and a regular hexagon shape, and the holes are straight channel structures parallel to each other. This structure greatly reduces the resistance of the pores flowing through and greatly improves the single-pore volume heat exchange efficiency of the regenerator.

Prime features:

1. Low thermal expansion,

2.Super specific heat capacity,

3. Large specific surface area,

4. Small pressure drop,

5. Low thermal resistance

6. Good thermal conductivity

7. Good thermal shock resistance

Application:

Steel plant, waste incinerator, waste heat treatment equipment, chemical plant, smelter, power plant, power industry boiler, gas turbine, engineering heat equipment, ethylene cracking furnace.

Company Profile

We, at Jinghui Industry Ltd is a leading advanced ceramic components' manufacturer in China over than 11 years.

The selection manufacturing methods include dry pressing, hot pressing, isostatic pressing, ceramic injection molding, extrusion with selection of materials. Also we have our own comprehensive high precison processing and firing production line. Such as metallizing, glazing, fine grinding, CNC machining, laser cutting and so on.

The quality products come from art of state of manufacturing processes, also it's in need of advanced inspection tool. The main inspection equipment include CMM, projector etc.

With our reliable products, professional service and good credit established with customers, we have been exporting our products to Europe, North American, Asia, South American, South African over than 50 countries

Our advantage

Contact information