Transportation:Ocean,Land,Air

Port:Shenzhen,HongKong

$6010-99Piece/Pieces

$50≥100Piece/Pieces

Model No.: Standard or custom-made

Brand: Jinghui ceramics

Place Of Origin: China

Species: Ceramic Plates

Application: Industrial Ceramic

Material: Alumina Ceramic

Processing Service: Bending, Cutting, Moulding

Features: High Thermal Conductivity, High Thermal Shock

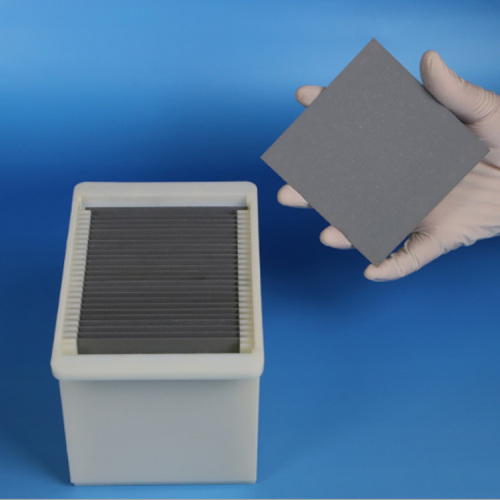

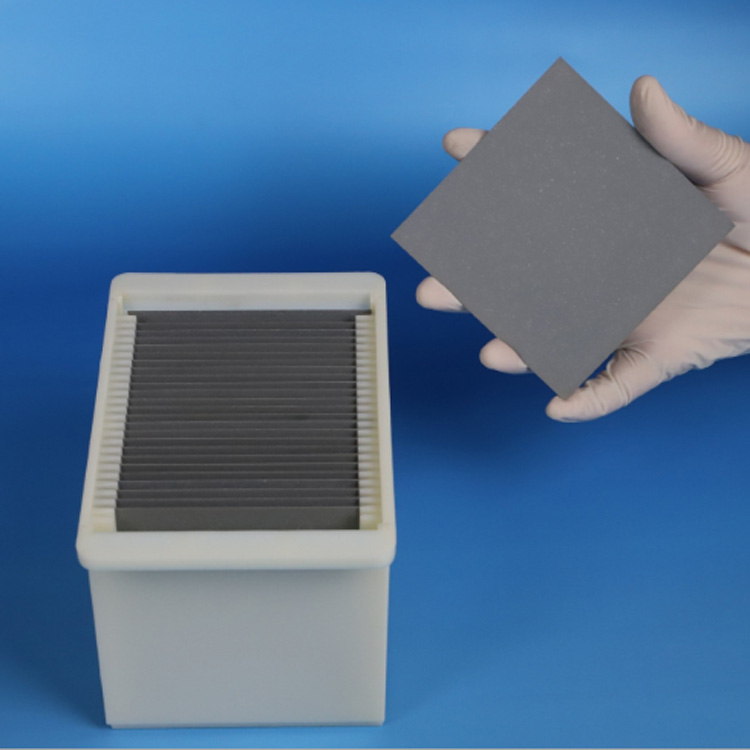

Product Name: Silicon Nitride Ceramic Plate

Material: Silicon Nitride Ceramic

Type: Engineering Ceramic Plate, Ceramic Substrate

Specification: As Per Customers' Requirement

Packaging: Export carton

Productivity: 100000 pieces/month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 50000 pieces/month

Certificate: RoHS

HS Code: 8547100000

Port: Shenzhen,HongKong

The main features of the silicon nitride plate

1. High thermal conductivity ( up to 70 W/m.k), 3 times that of Alumina Ceramic Substrate;

2. The thermal expansion coefficient (3.1×10-6/℃) matches the semiconductor silicon material (3.5-4.0×10-6/℃);

3. The bending strength is higher than that of the alumina substrate, which is twice that of the alumina substrate;

4. Excellent electrical performance, with extremely high insulation resistance and low dielectric loss;

5. High thermal shock resistance, from 0 ℃ to 200 ℃ and then cool down, repeat 10000 times;

6. Chemical resistance, resistant oxidization , acid, alkali corrosion, service life-span up to 10 years.

7. The compatibility of circuit materials is good, and multi-layer wiring can be performed to achieve miniaturization of the package;

The specification of the silicon nitride ceramic plate

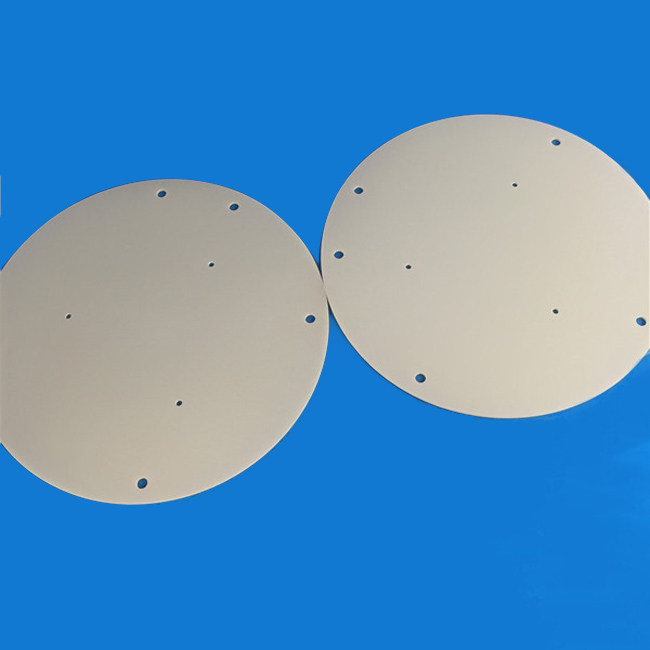

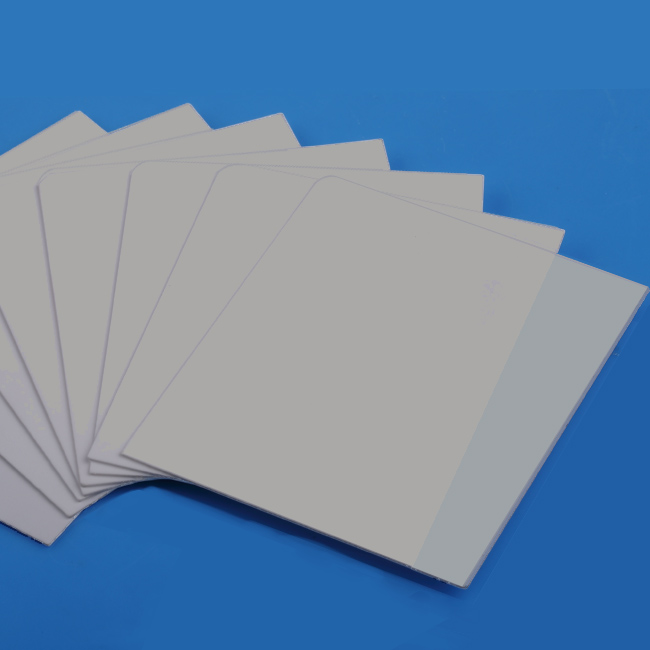

1. We are supplying with many round ceramic wafer, square & rectangular Ceramic Substrate

2. The typical thickness of silicon nitride substrate covers 0.30mm, 0.5mm, 0.635mm, 1.0mm

3. The biggest diameter of round ceramic wafer can be up to 400mm in 3mm, 4mm, 5mm thick

4. The max. side-length of square and rectangular ceramic substrate can be 400mm by 500mm

5. Surface treatment: it can be one-side, or double side polished to be Ra0.6 or better

The description of the silicon nitride ceramic plate

Silicon Nitride (Si3N4) is a widely used technical ceramic material in high temperature application, it has high strength in both room temperature and high temperature condition, the strength of silicon nitride can be kept up to 1200℃; the low coefficient of thermal expansion make it a ceramic material possessing excellent thermal shock resistance; at the same time, it also has good thermal conductivity.

Except for the excellent properties in thermal application, silicon nitride also has good mechanical, chemical, electrical properties. It has good strength, good flexture strength and wear resistance;it is a good performance electrical insulation ceramic.

The silicon nitride application

Silicon Nitride Ceramics are widely used for precision shafts and axles in high wear environments,rotating bearing balls and rollers,cutting tools, engine wear parts, tappet shims,turbine blades, vanes, buckets, metal tube forming rolls and dies.

Remark:

We supply a broad range of advanced ceramic plates, including Alumina Ceramic plates, zirconia ceramic plates

aluminum nitride ceramic plates besides silicon nitride ceramic plates.

General

Properties

Unit

Value

Mechanical

Volume Density

g/cm3

≥3.22

Color

Black gray Compressive Strength

MPa ≥2500 Bending Strength

MPa 600 Elastic Modulus

MPa 300 Fracture toughness

Mpam1/2 7 Thermal

Max. service temperature (Non-loading)

℃

1300 Thermal Conductivity (25℃)

W/m.k

≥70

Coefficient of Thermal Expansion (CTE)

1*10-6 m/k

3.1 Specific heat

1 x 103J/(kg·K)

0.5 Electrical

Volume Resistivity (25℃)

ohm.cm

- Insulation Breakdown

KV/mm

- Dielectric constant (1Mhz)

(E)

6

1. Support customized prototyping and R&D needs

2. High Precision CNC Machining Workshop

4. Customized capability from small size to big-size

Remark:

We have own in-house comprehensive types of manufacturing equipment, including forming machines,

vacuum sintering furnace, High precision machining equipment, polishing machines, metalizing production lines.

1. High Precision Inspection Tools

2. OQC Inspection Workshop

Remark:

1. We have complete and rigorous quality-control system, including IQC, IPQC, QA and OQC per ISO9001.

2. We also have professional quality assurance team and precision inspection equipments for quality-control.

FAQs (Frequently Asked Questions)

Q1:Is it available to provide customized products?

A: We always support custom-made demand as per different dimensions, design and surface treatment.

Q2. When can I get the price?

A: We regularly quote within 24 hours after we get your inquiry. If you are in urgent need of get the price,

please call us or tell us in your email so that we will proceed your inquiry as priority.

Q3. How long can I expect to get the sample?

A: After you pay the sample charge and send us the confirmed files, the samples will be ready for delivery in 4 weeks.

Q4:How long does the whole procedure being worked out?

A: After you place an order, the manufacturing time is about 25 working days.

Q5. Are you a factory or trading company?

A: We are a professional manufacturer. You are welcome to visit our factory.