Payment Type:L/C,T/T,Paypal,Western Union

Incoterm:FOB,CFR,CIF,EXW,FCA,CPT,CIP

Min. Order:100 Piece/Pieces

Transportation:Ocean,Land,Air

Port:Shenzhen Port,Hongkong

Model No.: Customized

Brand: Jinghui ceramics

Packaging: Vacumm packaging with export carton

Productivity: 50,000pcs/month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 200,000pcs/month

Certificate: RoHS

HS Code: 8547100000

Port: Shenzhen Port,Hongkong

Payment Type: L/C,T/T,Paypal,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

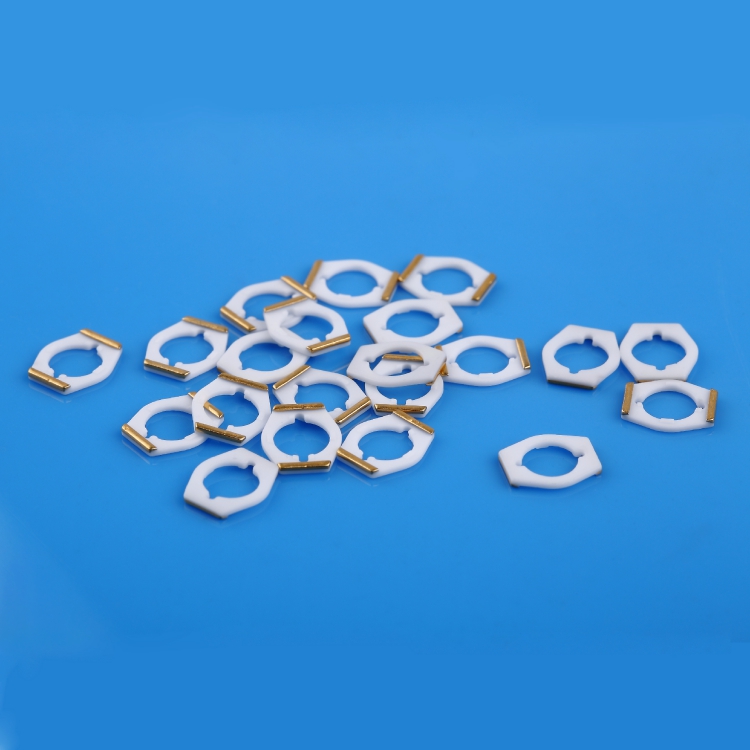

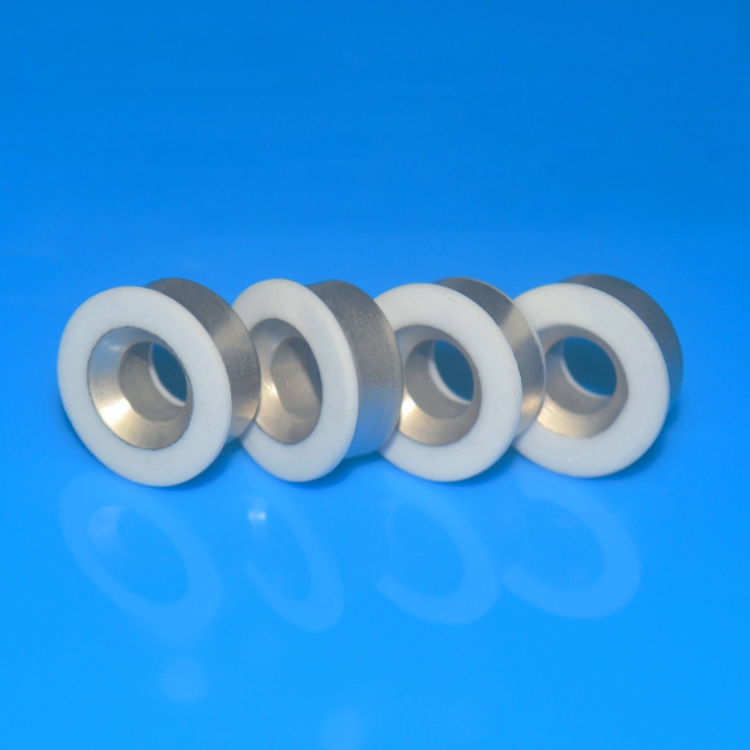

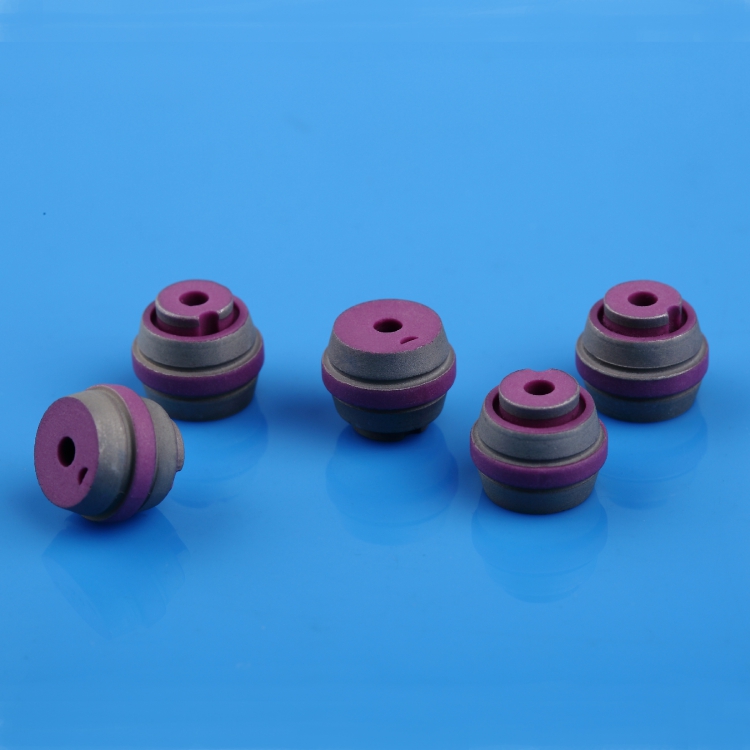

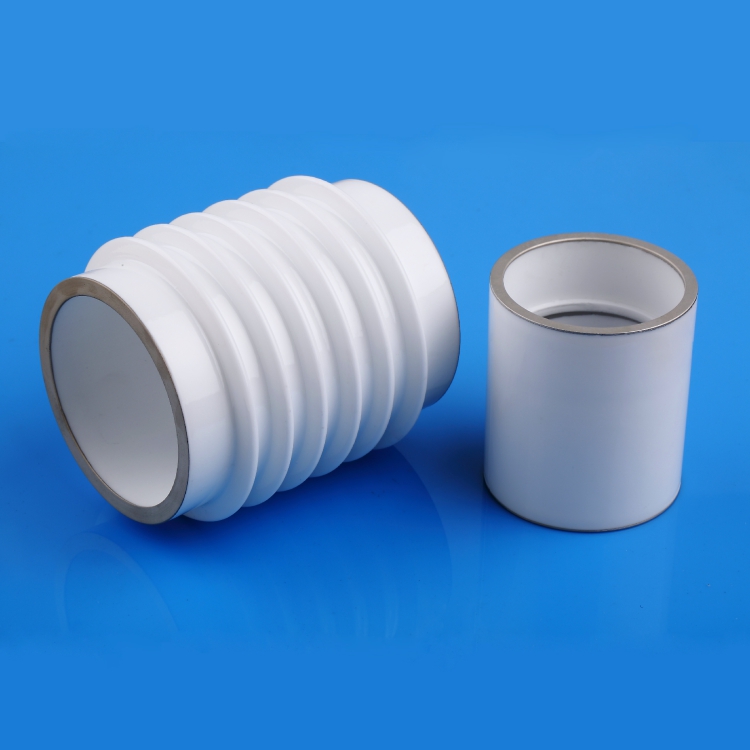

Due to ceramic tube with Mo/Mn metallization can be brazed with metal parts directly, sometimes, a few customers just request Alumina Ceramic Tube to be Mo/Mn metallized. This Metallized Ceramic Tube is commonly made of 95% alumina via dry pressing, injection, or hot pressing. A selection of coating on ceramic body is available, the typical plating is nickle plating, silver plating, gold plating , tin plating, copper plating.

We are capable of offering high precision metallized ceramic tube via variety of grinding, CNC machining, cutting processes. The finest tolerance can be +/-0.001 for length, +/-0.01 for inner and outer diameter.

Small part-size to large part-size is availability, the min. diameter can be 1 mm, the largest diameter is up to 800 mm.The typical plating as below:

1. Raw ceramic + Mo/Mn metallization 2. Raw ceramic + Mo/Mn metallization + Nickle plating

Prototyping to mass production is an advantage to us because of our own comprehensive production line.

Technical Key Parameters of Metalized Ceramics

| Leak Rate | ≤1x10-11Pa.m3/s | Metal Layer Tensile Strength | ≥120Mpa |

| Volume Resistivity | ≥108Ω•cm | Coefficient of Thermal Expansion | (6.5 ~ 8.0) × 10-6 /°C |

| Insulation Strength | ≥18kV/mm (D•C) | Dielectric Constant | 9~10(1MHz, 20°C) |

| Cosmetic Quality:1. No cracks, no bubbles; 2. Evenly distributed glaze; 3. No contamination | |||

Features of alumina metalized ceramics

●High bonding / brazing strength ●Low leakage rate ●High Insulation strength●High mechanical strength

●Low thermal expansion ●Resistant to corrosion free of rust ●Min. electric resistance and vacuum tightness

The application of metalized ceramic tube

Widely used in vacuum interrupters, Electron tubes,Gas discharge tube, Vacuum capacitor,Vacuum thyristors,

Surge arresters,Thyristor housings,Diode housings,Power grid tubes,Traveling wave tubes,Insulator rings and cylinder,X-ray tubes and so on

Q 1. Is it available to provide customize products?

A: We could support custom-made demand as per different dimensions, design and metallization and plating.

Q 2. When can I get the price?

A: We regularly quote within 24 hours after we get your inquiry.

Q 4. What about the transportation and delivery date?

A: Normally we use Int`l express by our forwarder, or with client`s account number. It is about 3~5 working days.

Q 5. How to ensure the quality?

A: The dimension out of any batch will be carried out sampling inspection per International AQL standard. 100% cosmetic inspection will be done.