Payment Type:L/C,T/T,Paypal,Western Union

Incoterm:FOB,CFR,CIF,EXW,FCA,CPT,CIP

Min. Order:100 Piece/Pieces

Transportation:Ocean,Land,Air

Port:Shenzhen Port,Hongkong Port

Model No.: Customized

Brand: Jinghui ceramics

Packaging: Vacumm packaging with export carton

Productivity: 50,000pcs/month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 200,000pcs/month

Certificate: RoHS

HS Code: 8547100000

Port: Shenzhen Port,Hongkong Port

Payment Type: L/C,T/T,Paypal,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

| Leak Rate | ≤1 x 10-11 Pa.m3/s | Metal Layer Tensile Strength | ≥150 Mpa |

| Volume Resistivity | ≥108Ω•cm | Coefficient of Thermal Expansion | (6.5 ~ 8.0) × 10-6 /°C |

| Insulation Strength | ≥18 kV/mm (D•C) | Dielectric Constant | 9~10(1MHz, 20°C) |

| Cosmetic Quality:1. No cracks, no bubbles; 2. Evenly distributed glaze; 3. No contamination | |||

● High bonding / brazing strength ● Low leakage rate ● High Insulation strength● High mechanical strength

● Low thermal expansion● Resistant to corrosion free of rust ● Min. electric resistance and vacuum tightness

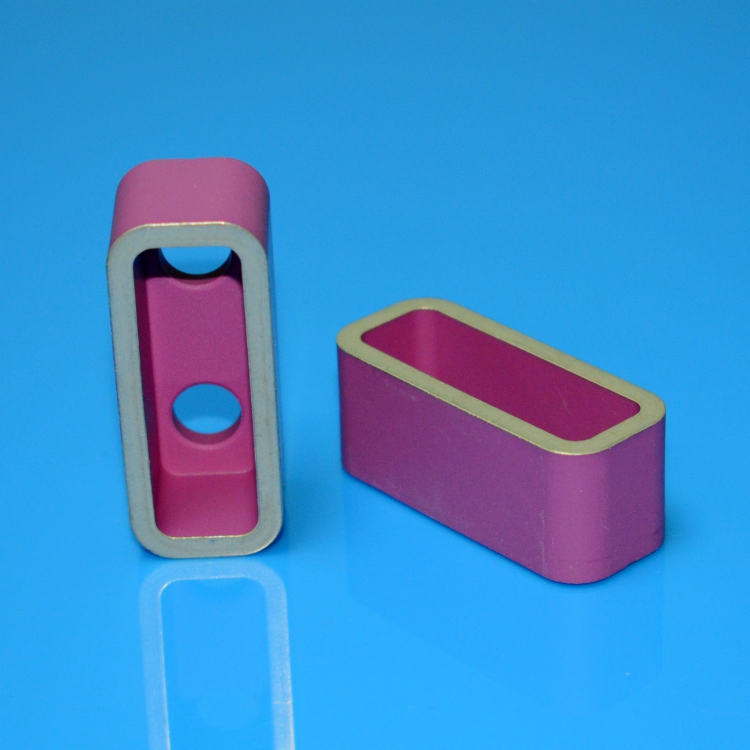

Depositing a metallic coating of Molybdenum-manganese(Mo-Mn) / Tungsten (W) based paints followed by nickel /gold plating, Afterwards, an interface offered that enables ceramic to metal or ceramic to ceramic joining by means of brazing via solder.

In common case, a layer of metallization layer is applied with a typical thickness of 10 to 30 µm after cured. The metallization sintering process is carefully controlled to achieve a balanced mixture of Molybdenum particles surrounded by a matrix of glass to ensure high bond strength between the metallized layer and the ceramic base. In order to increase the wettability at subsequent brazing processing, we make the nickel plating to be 2~6 um. We can offer a selection of metallization types as below:

1. Ceramic body base + Mo/Mn metallization.......................2. Ceramic body base + Ag plating

3. Ceramic body base + Sn plating.......................................4. Ceramic body base + Mo/Mn metallization + Nickle plating

5. Ceramic body base + W metallization + Gold plating

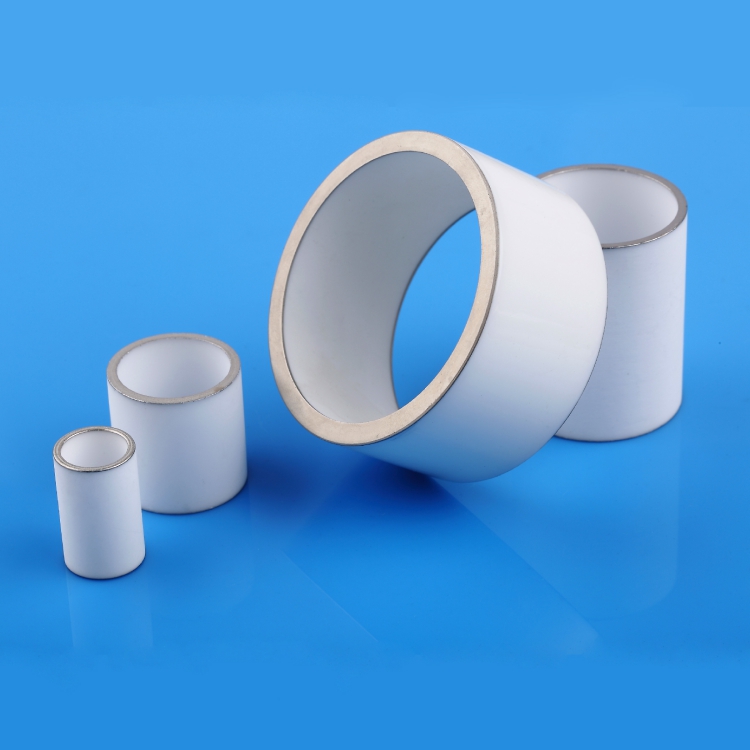

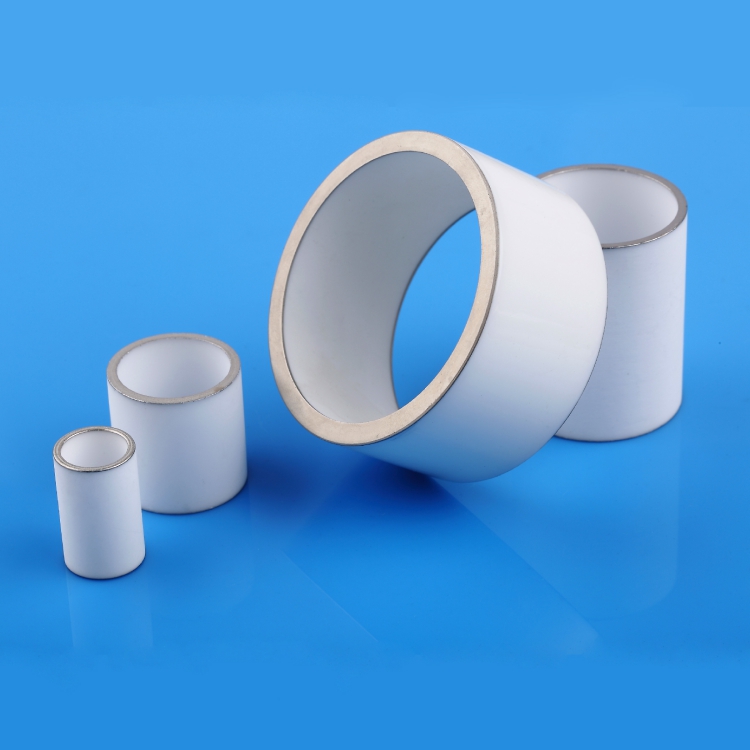

We are capable of offering high precision metallized ceramic bushing via fine grinding, CNC machining, cutting processes.

The tolerance can be +/-0.01 for overall dimensions.

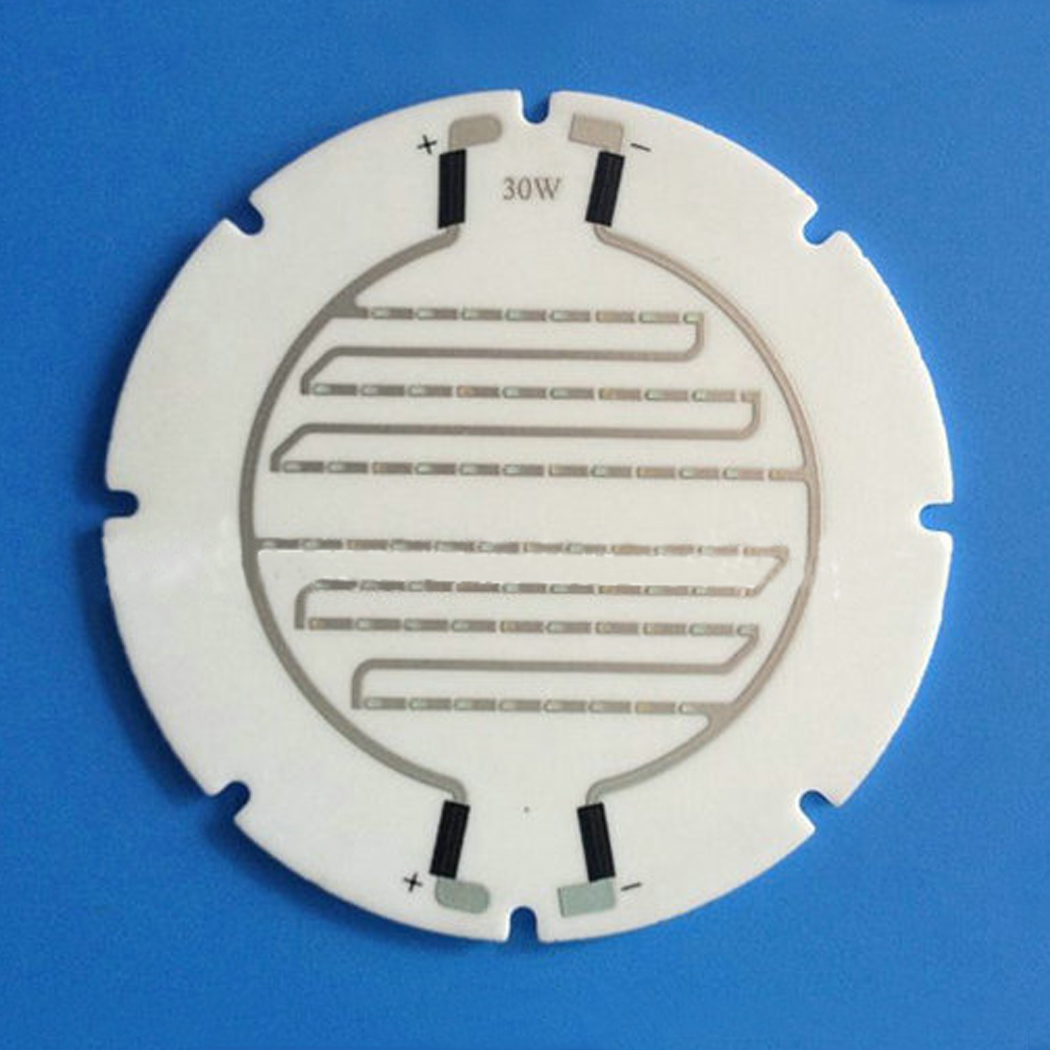

Remark: Apart from variety of metallized ceramic tubes, we also manufacture Metallized Ceramic Ring, Metallized Ceramic Substrate,

metallized ceramic disc, metallized ceramic cylinder.

Q 1. Is it available to provide customize products?

A: We could support custom-made demand as per different dimensions, design and metallization and plating.

A: After you place an order, the manufacturing time is about 25 working days.

Q 3. What about the transportation and delivery date?

A: Normally we use Int`l express by our forwarder, or with client`s account number. It is about 3~5 working days.

Q 4. How to ensure the quality?

A: The brazing strength test and hermetricity test will be done before shipping.

The KPI will be used in the production line ,also sampling inspection for dimensions will be performed per AQL 0.65.

Q 5. What any other products do you produce?

A: We also manufacture a variety of ceramic grinding burrs, advance ceramic plates, Zirconia Ceramic Components.