Transportation:Ocean,Land,Air,Express

Port:Shenzhen Port,Hongkong Port

$3010-99Piece/Pieces

$25100-499Piece/Pieces

$20≥500Piece/Pieces

Model No.: Standard or custom-made

Brand: Jinghui ceramics

Place Of Origin: China

Species: Ceramic Parts

Application: Industrial Ceramic

Material: Alumina Ceramic

Processing Service: Moulding

Color: White, Pink Optional

Metallization Type: Mo/Mn ,W Optional

Coating Type: Nickle Plating

Thickness Of Metallization: 20~40um

Thickness Of Plating: Thin Or Thick Film Avaiable

Material: Min. 95% Alumina

Type: Industrial Ceramic Part

Surface Finish: Glazed

Feature: High Bonding Strength

Application: Vacuum Interrupter Devices

Packaging: Vacumm packaging

Productivity: 50,000pcs/month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 20000pcs/month

Certificate: RoHS

HS Code: 8547100000

Port: Shenzhen Port,Hongkong Port

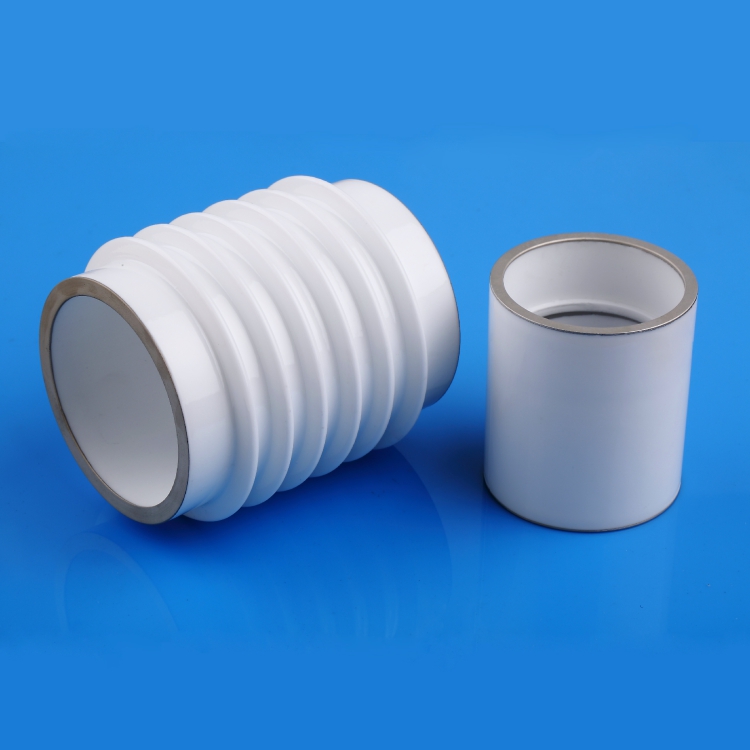

This metallized ceramic cylinder is commonly used in vacuum switch, vacuum interrupter, vacuum breaker. It is made of min. 95% alumina via dry pressing, or hot pressing. We are able to manufacture a diversity of different specification metallized ceramic cylinders, including different dimensions, different type, different metal coating on surface.

Small part-size to large part-size is availability, the min. diameter can be 1 mm, the largest diameter is up to 800 mm.The typical plating as below:

1. Raw ceramic + Mo/Mn metallization 2. Raw ceramic + Ag coating 3. Raw ceramic + W metallization + Au coating

4. Raw ceramic + Mo/Mn metallization + Nickle coating

We are capable of offering high precision metallized ceramic tube via variety of grinding, CNC machining, cutting processes. The finest tolerance can be +/-0.001 for length, +/-0.0051 for inner and outer diameter.

Technical Key Parameters

| Leak Rate | ≤1x10-11Pa.m3/s | Metal Layer Tensile Strength | ≥120Mpa |

| Volume Resistivity | ≥108Ω•cm | Coefficient of Thermal Expansion | (6.5 ~ 8.0) × 10-6 /°C |

| Insulation Strength | ≥18kV/mm (D•C) | Dielectric Constant | 9~10(1MHz, 20°C) |

| Cosmetic Quality:1. No cracks, no bubbles; 2. Evenly distributed glaze; 3. No contamination | |||

Features :

●High bonding / brazing strength ●Low leakage rate ●High Insulation strength●High mechanical strength ●Low thermal expansion ●Resistant to corrosion free of rust●Min. electric resistance and vacuum tightness

Application:

Widely used in vacuum interrupters, Electron tubes,Gas discharge tube, Vacuum capacitor,Vacuum thyristors, Surge arresters,Thyristor housings,Diode housings,Power grid tubes,Traveling wave tubes,Insulator rings and cylinder,X-ray tubes and so on.

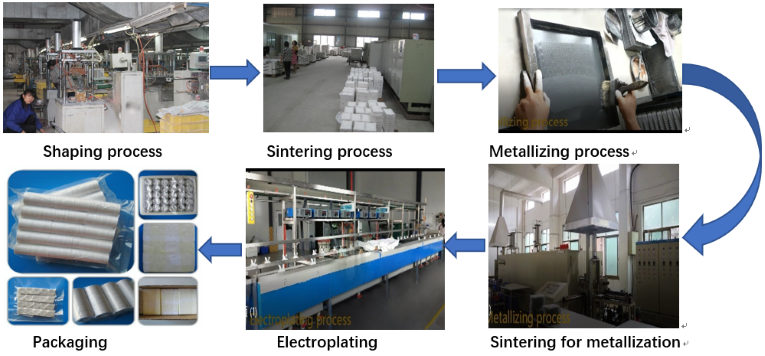

We have a complete comprehensive of production equipment for Metallized ceramics from shaping to electroplating.It helps us to make the dimensional consistency very well. Also, helping us to offer a competitive price.

Q 1. Is it available to provide customize products?

A: We could support custom-made demand as per different dimensions, design and metallization and plating.

Q 2. When can I get the price?

A: We regularly quote within 24 hours after we get your inquiry.

Q 4. What about the transportation and delivery date?

A: Normally we use Int`l express by our forwarder, or with client`s account number. It is about 3~5 working days.

Q 5. How to ensure the quality?

A: The dimension out of any batch will be carried out sampling inspection per International AQL standard. 100% cosmetic inspection will be done.