Min. Order:100 Piece/Pieces

Transportation:Ocean,Land,Air,Express

Port:Shenzhen,Hongkong

$1-50 /Piece/Pieces

Model No.: Customized

Brand: Jinghui ceramics

Place Of Origin: China

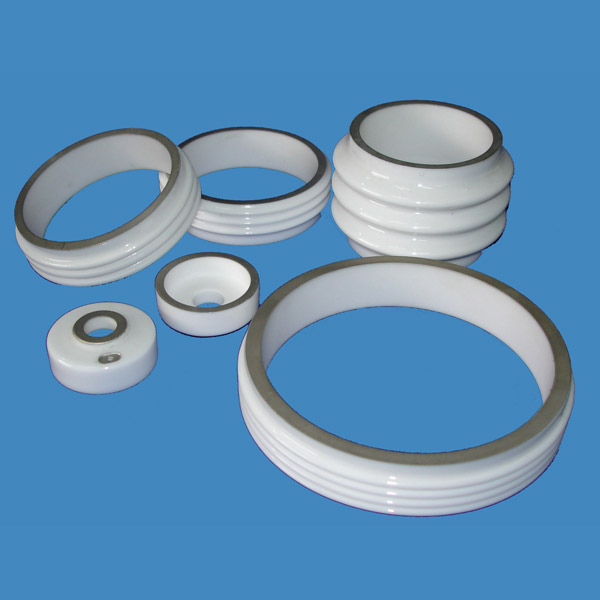

Types Of: High Frequency Ceramics, Dielectric Ceramics, Insulating Ceramics

Material: Alumina, Zirconium Oxide, Aluminum Nitride, Silicon Nitride, 95% Alumina, Aln Ceramics

Color: White

Tolerance: Best To Be 0.01mm

Max. OD: 100mm

Min. Wall Thickness: 0.3mm

Precision Process: Fine Grinding,Maching,Laser Cutting

Features: Excellent Insulation, Heat Dissipation

Application: Ceramic Circuit Board

Certificate: Iso9001:2015, Sgs

Packaging: Export carton

Productivity: 100,000 sets/month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 500,000 sets/month

Certificate: RoHS

HS Code: 8547100000

Port: Shenzhen,Hongkong

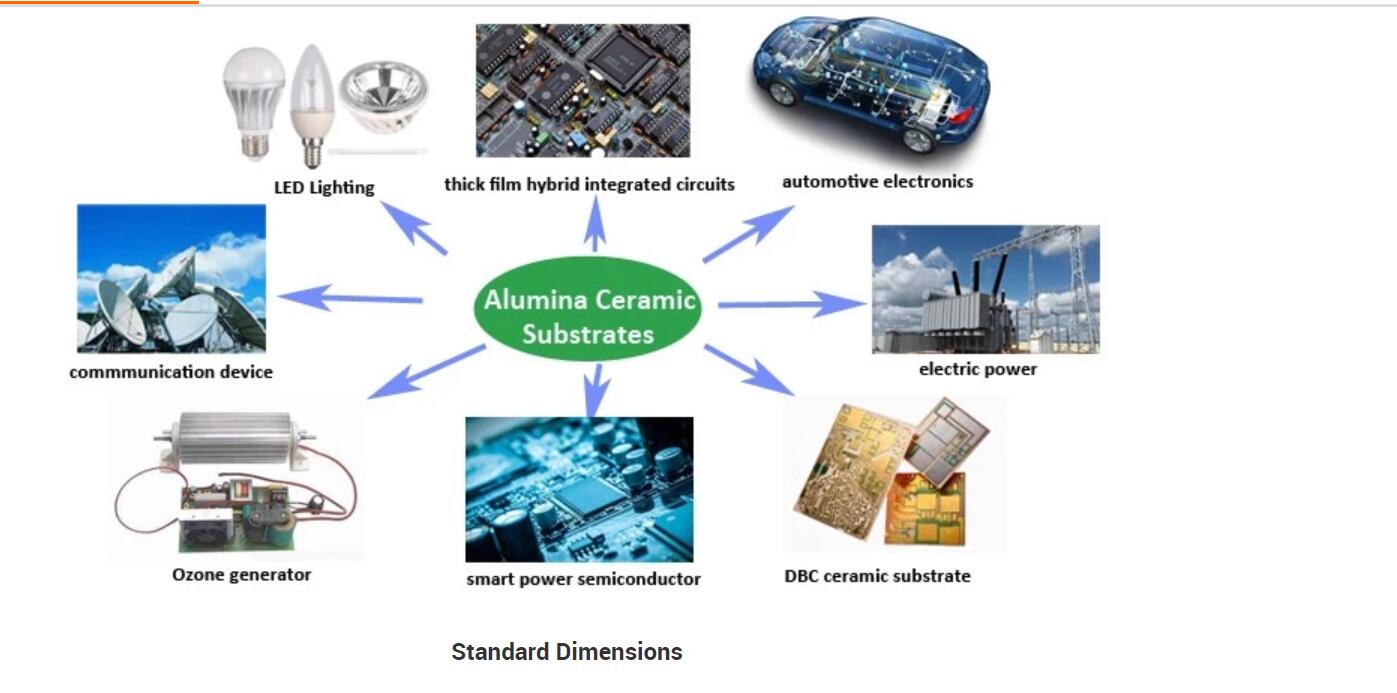

Ceramic circuit boards are different from traditional FR-4 (plastics). Ceramic materials have good high-frequency performance and electrical properties, and have high thermal conductivity, excellent chemical stability and thermal stability, and other properties that organic substrates do not have. It is an ideal packaging material for a new generation of large-scale integrated circuits and power electronic modules. Therefore, in recent years, ceramic circuit boards have received extensive attention and rapid development.

DBC Process Capability and Specification of DBC ceramic substrates

S/N Item Parameters 96% alumina (Al2O3), Aluminum nitride(AlN) ,Beryllium oxide (BeO) and Silicon nitride(Si3N4) 2 Processing type Direct Bonded Cooper (DBC) 3 Min. Distance 0.15mm 4 The thickness of conductor layer 0.075 ~ 600 um 5 Solder White, Black, Green 6 Surface treatment ENIPIG, Deposition 7 Typical thickness of raw substrate 0.30mm, 0.38mm, 0.50mm, 0.63mm and 0.80mm 8 Regular size 130mm x 140mm, 140mm x 190mm

1 Material type

1. Higher thermal conductivity, especially aluminum nitride DBC Ceramic Substrate is up to 180 W/k.m

2. Perfect matching thermal expansion coefficient that is similar of the Si chips in the high-power modules

3. Stronger and lower resistance metal film, copper is one of best conductor in the electrical fileds

4. The solderability of the substrate is good, and it's suitable for the operation under very high temperature

5. Good insulation, it's a ideal option for using in high-voltage and high-current application

6. Small high frequency loss because of the direct bonded copper file on ceramic substrates

7. It does not contain organic ingredients, is resistant to cosmic rays, has high reliability in aerospace and has a long service life

8. The copper layer does not contain an oxide layer and can be used for a long time in a reducing atmosphere

High-density Hybrid Circuits, Microwave Power Devices, Power Semiconductor Devices, Power Electronic Devices, Optoelectronic Components,Semiconductor Refrigeration Products

Q1. Is it available to provide customize products?

A: We support customized DBC ceramic substrates with selection raw materials, designated thickness of DBC types.

Q2. How long can I expect to get the sample?

A: The samples could be ready in 2 weeks when all technical details are confirmed.

Q3. How long does the whole procedure being worked out?

A: It depends on the quantity level of order. In common case, the manufacturing time is about 25 working days after order confirmed.

Q4. How to ensure quality?

A: The reliability test, dimensional & cosmetic inspection will be performed with a certain sampling size every order.

Q5. Do you supply other ceramic components?

A: Besides DBC ceramic substrates, we also produce a variety of Metalized Ceramic Insulator, high precision machined ceramic parts.

Q6. Are you a factory or trading company?

A: We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.