Min. Order:100 Piece/Pieces

Transportation:Ocean,Land,Air,Express

Port:Shenzhen,Hongkong

$1-50 /Piece/Pieces

Model No.: Customized

Brand: Jinghui ceramics

Place Of Origin: China

Types Of: High Frequency Ceramics, Dielectric Ceramics, Insulating Ceramics

Material: Alumina, Aluminum Nitride, Silicon Nitride, 95% Alumina, Aln Ceramics

Tolerance: Best To Be 0.01mm

Min. Wall Thickness: 0.3mm

Precision Process: Fine Grinding,Maching,Laser Cutting

Features: Excellent Insulation, Heat Dissipation

Application: Ceramic Circuit Board

Certificate: Iso9001:2015, Sgs

Color: Gray, Black

Packaging: Export carton

Productivity: 100,000 sets/month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 500,000 sets/month

Certificate: RoHS

HS Code: 8547100000

Port: Shenzhen,Hongkong

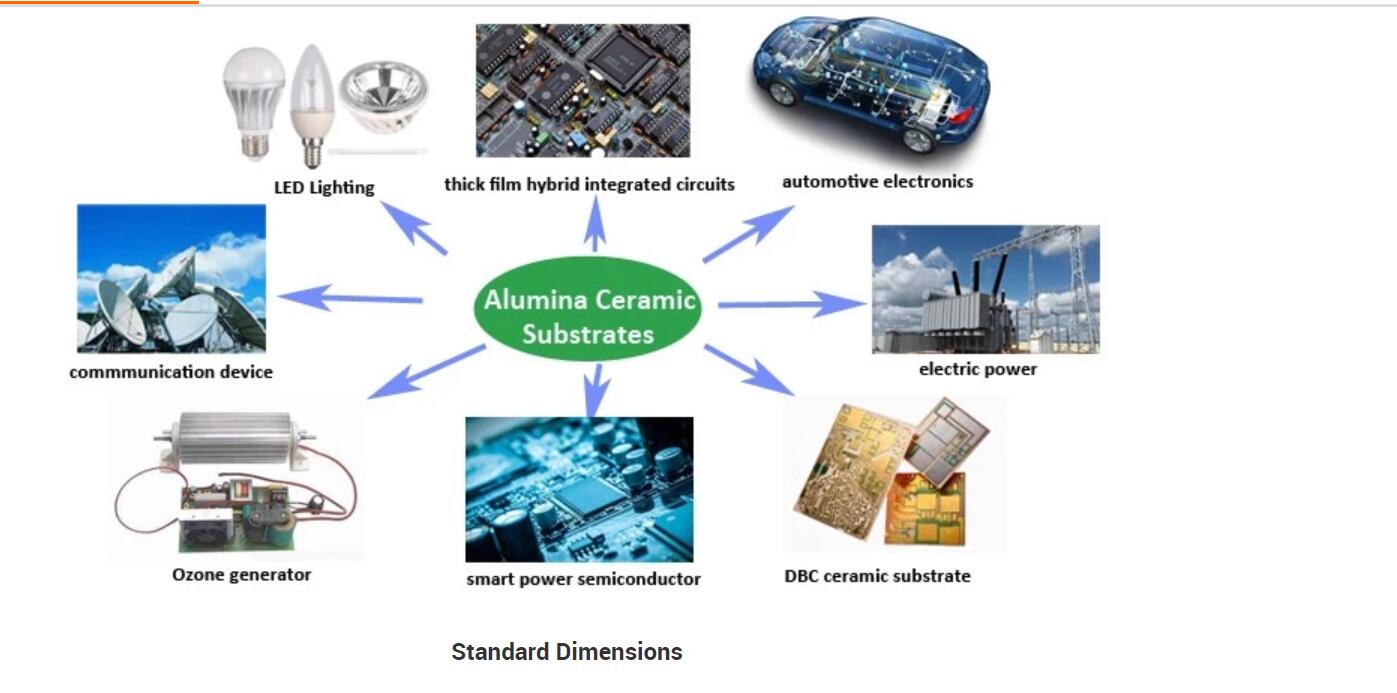

The DBC substrate is a metalized substrate in which copper plating is bonded to alumina or aluminum nitride ceramic substrate directly under high temperature sintering to form a film. They are features of high thermal conductivity, high current capacity, and high voltage insulation. DBC ceramic substrate has been proven for ages as a proper solution for electrical insulation and thermal management of high power devices.

DBC Process Capability and Specification of DBC ceramic substrates

S/N Item Parameters Aluminum nitride(AlN), Aluminum oxide (Al2O3) ,Beryllium oxide (BeO) and Silicon nitride(Si3N4) 2 Processing type Direct Bonded Cooper (DBC) 3 Min. Distance 0.15mm 4 The thickness of conductor layer 0.075 ~ 600 um 5 Solder White, Black, Green 6 Surface treatment ENIPIG, Deposition 7 Typical thickness of raw substrate 0.30mm, 0.38mm, 0.50mm, 0.63mm and 0.80mm 8 Regular size 130mm x 140mm, 140mm x 190mm

1 Material type

1. Exceptional hardness, flexural strength, compressive strength and fracture toughness;

2. Great metalization adhesion between copper and ceramic: initial and after thermal cycling;

3. Chemical stability, it won't react with almost acids and alkalis, free of rust forever;

4. High thermal conductivity, the value of AlN DBC ceramic substrate is up to 180W/k.m;

5. High current handling capacity with selection of base layer of cooper;

6. High heat dissipation, it can play a role of heat ceramic sink in the devices.

DBC ceramic substrates are widely used in power electronic devices and LEDs. , Solar modules, semiconductor refrigerators and other product fields..

Q1. Is it available to provide customize products?

A: We support customized DBC ceramic substrates with selection raw materials, designated thickness of DBC types.

Q2. How long can I expect to get the sample?

A: The samples could be ready in 2 weeks when all technical details are confirmed.

Q3. How long does the whole procedure being worked out?

A: It depends on the quantity level of order. In common case, the manufacturing time is about 25 working days after order confirmed.

Q4. How to ensure quality?

A: The reliability test, dimensional & cosmetic inspection will be performed with a certain sampling size every order.

Q5. Do you supply other ceramic components?

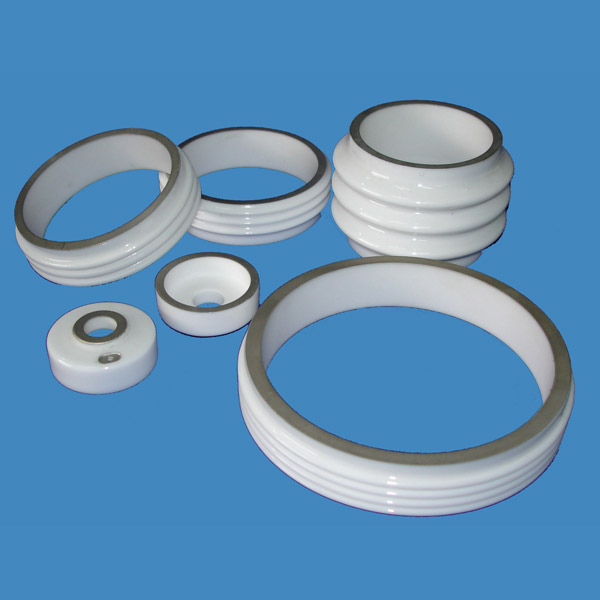

A: Besides DBC ceramic substrates, we also produce Metallized Ceramic Insulator, Silicon Nitride Ceramics and Boron Nitride Ceramics.

Q6. Are you a factory or trading company?

A: We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.