Payment Type:T/T,Paypal,Western Union

Incoterm:FOB,CFR,CIF,EXW,FCA,CPT,CIP

Min. Order:100 Set/Sets

Transportation:Ocean,Land,Air

Port:Shenzhen Port,Hongkong Port

$5≥100Set/Sets

Model No.: Customized

Brand: Jinghui ceramics

Packaging: Export carton

Productivity: 100,000 sets/month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 500,000 sets/month

Certificate: RoHS

HS Code: 8547100000

Port: Shenzhen Port,Hongkong Port

Payment Type: T/T,Paypal,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

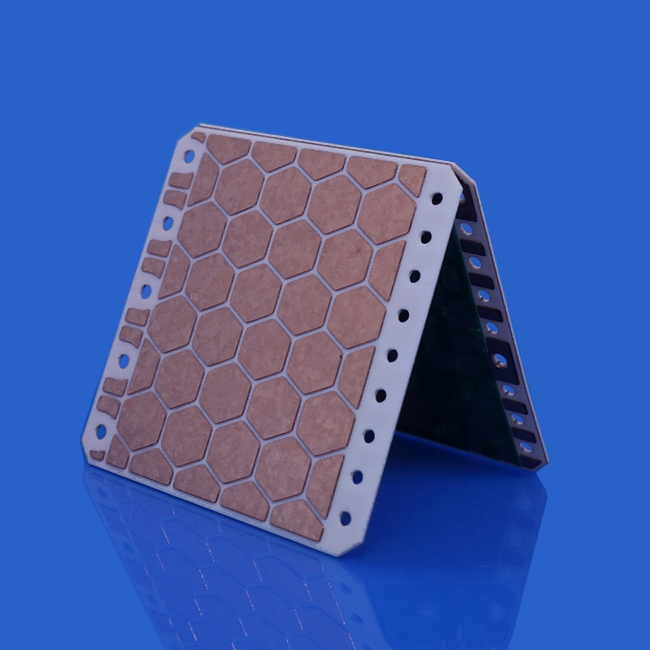

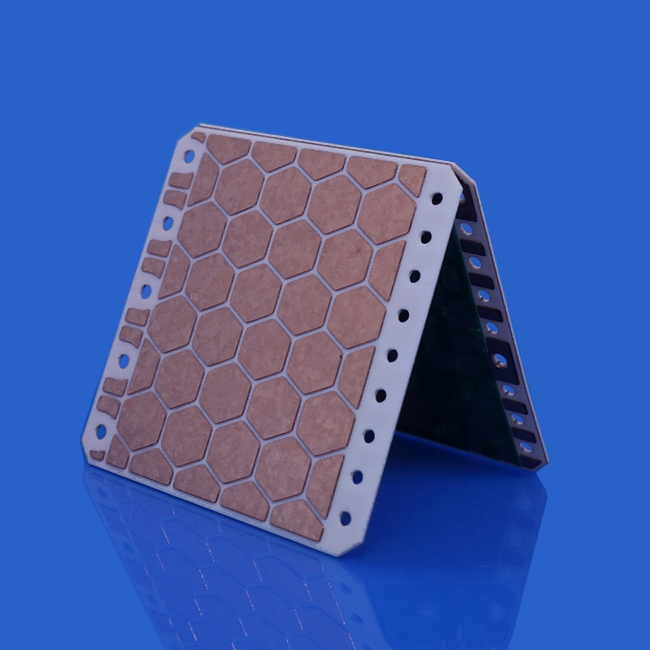

The description of DBC Ceramic Substrate:

1.Material: 96% alumina, aluminum oxide

2.Base layer:Molybdenum-Mananese(Mo/Mn) and Tungsten (W) optional

3. Thickness of metallization: from 10 to 40 micrometers (µm)

4. Thickness of metallic plating: nickle with 2~6 µm, copper with customized thickness

5.These Metallized ceramics are ideal for high voltage, high vacuum and high pressure applicationos.

So far the most widely-used and effective method for creating a leak-tight, robust joint between ceramic and metal is by brazing. A thin layer of metal deposited on a ceramic part enables brazing between ceramic and metal part that h as a different coefficient of thermal expansion.

A layer of Molybdenum-Manganese is deposited with a typical thickness of 8 to 30 µm after sintering.The metallized surface receives a secondary coating of nickel to seal and improve wettability for later brazing.

Typical application:

High-Density Hybrid Circuits, Microwave Power Devices, Power Semiconductor Devices, Power Electronic Devices, Optoelectronic Components,

Semiconductor Refrigeration Products

Q1. Is it available to provide customize products?

A: We always support custom-made metalized ceramic substrate as per different dimensions, design and metallization and plating.

Q2. When can I get the price?

A: We regularly quote within 24 hours after we get your inquiry. If you are in urgent need of getting the price, please call us or tell us in your email so that we will proceed with your inquiry as a priority.

Q3. How long can I expect to get the sample?

A: After you pay the sample charge and send us confirmed files, the samples will be ready for delivery in 4 weeks. The samples will be sent to you via express and arrive in 3-5 workdays. You can use your own express account or prepay us if you do not have an account.

Q4. How long does the whole procedure being worked out?

A: After you place an order, the manufacturing time is about 25 working days.

Q5. How to ensure quality?

A: The dimension out of any batch will be carried out sampling inspection per International AQL standard. A 100% cosmetic inspection will be done.

Q6. Are you a factory or trading company?

A: We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.