Payment Type:T/T,Paypal,Money Gram,Western Union

Incoterm:FOB,CFR,CIF,EXW,FCA,CPT,CIP

Min. Order:100 Piece/Pieces

Transportation:Ocean,Land,Air

Port:Shenzhen Port,HongKong,Shanghai

$3100-499Piece/Pieces

$2.5500-999Piece/Pieces

$21000-4999Piece/Pieces

$1.65≥5000Piece/Pieces

Model No.: Customized

Brand: Jinghui ceramics

Packaging: Vacumm packaging with export carton

Productivity: 50,000pcs/month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 200,000pcs/month

Certificate: RoHS

HS Code: 8547100000

Port: Shenzhen Port,HongKong,Shanghai

Payment Type: T/T,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

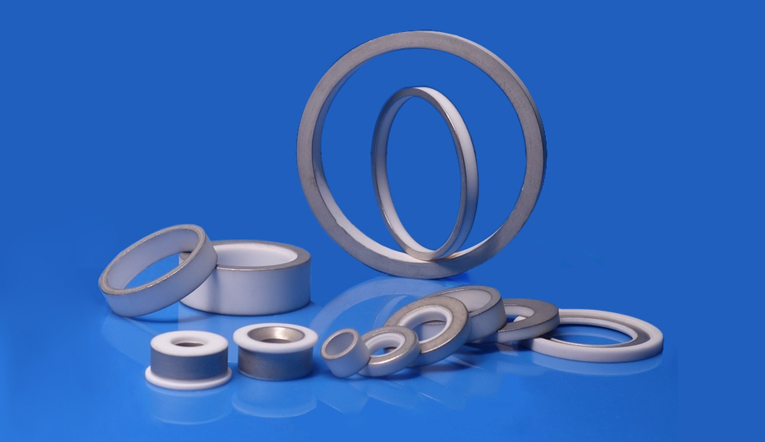

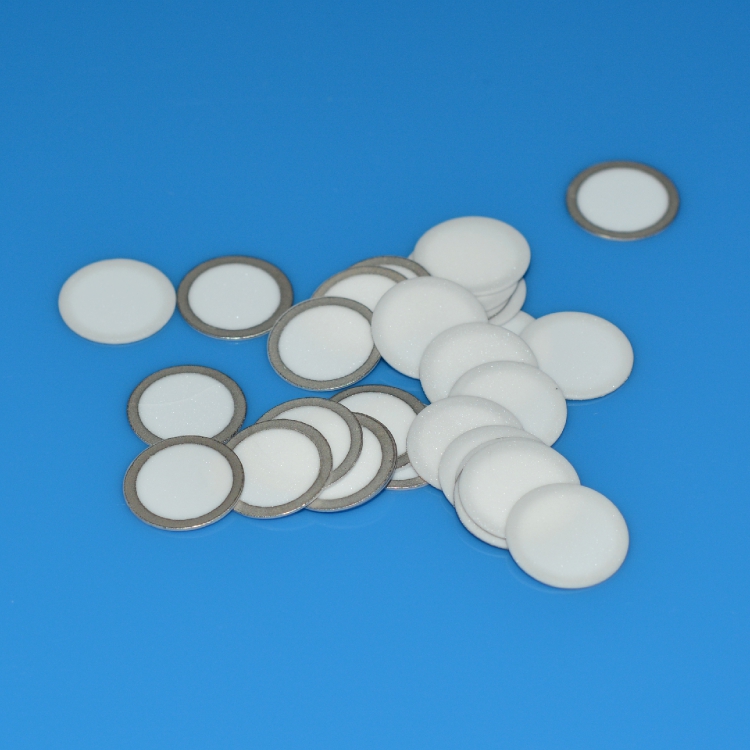

We are specializing in various of Metallized Ceramic Ring, Metallized Ceramic Tube, Metallized Ceramic Substrate over than 14 years. Based on our advanced technology and veteran manufacturing experience, all Metallized ceramics we offer a high bonding strength and exceptional hermeticity.

We offer a selection of metallization types to meet different needs from different customers, the typical as below:

1. Ceramic base + Mo/Mn metallization .......................................................................... 3.Ceramic base + Silver plating

2.Ceramic base + Mo/Mn metalization +Nickle plating................................................................4.Ceramic base + Tungsten metallization +Gold plating

● Excellent bonding strength ● Exceptional hermeticity and air tightness ● Great electrical insulation and high volume resistivity

● Superior corrosion resistance and free of rust ● Good thermal shock properties and low thermal conductivity

Capability for Metalized Ceramic Components

●Supply variety of different complex configuration ●Small part size to very large part size availability

●General tolerance to high precision capability ●Prototyping to mass production capability

The applications of metalized ceramics

It's widely used in power grid tubes , vacuum interrupters , medical linear accelerators, power tubes, photomultipliers,

components for insulators and sensors.

Q 1. Is it available to provide customize products?

A: We could support custom-made demand as per different dimensions, design and metallization and plating.

Q2: Do you produce any other metalized ceramics?

A: Yes, we also manufacture metalized ceramic tube, metalized Ceramic Substrate , metalized ceramic cylinders.

Q 3. How long does the whole procedure being worked out?

A: After you place an order, the manufacturing time is about 25 working days.

Q 4. What about the transportation and delivery date?

A: Normally we use Int`l express by our forwarder, or with client`s account number. It is about 3~5 working days.

Q 5. How to ensure the quality?

A: Sampling inspection will be carried every batch per AQL 0.65. 100% cosmetic inspection will be done.