Min. Order:100 Piece/Pieces

Transportation:Ocean,Land,Air,Express

Port:Shenzhen Port,Hongkong

Model No.: Customized

Brand: Jinghui ceramics

Place Of Origin: China

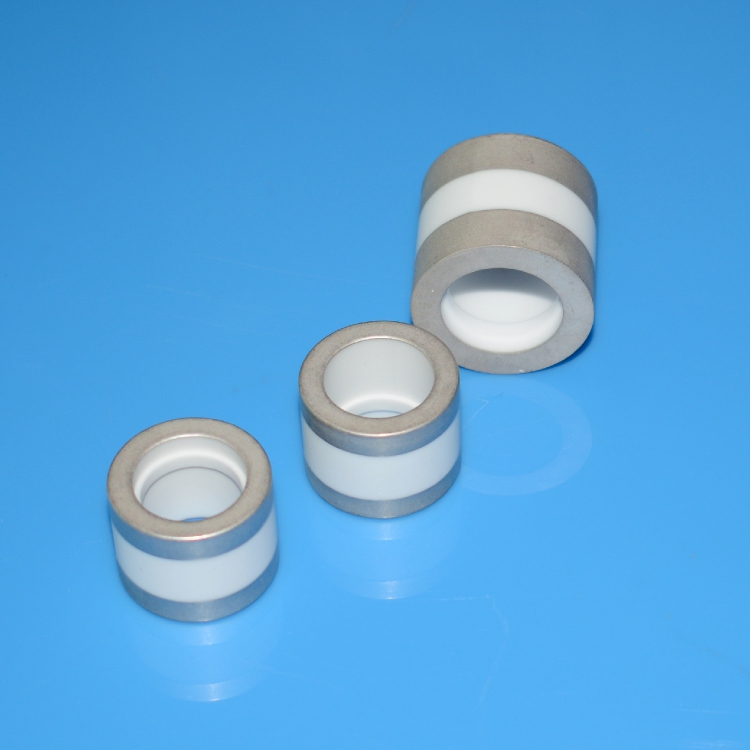

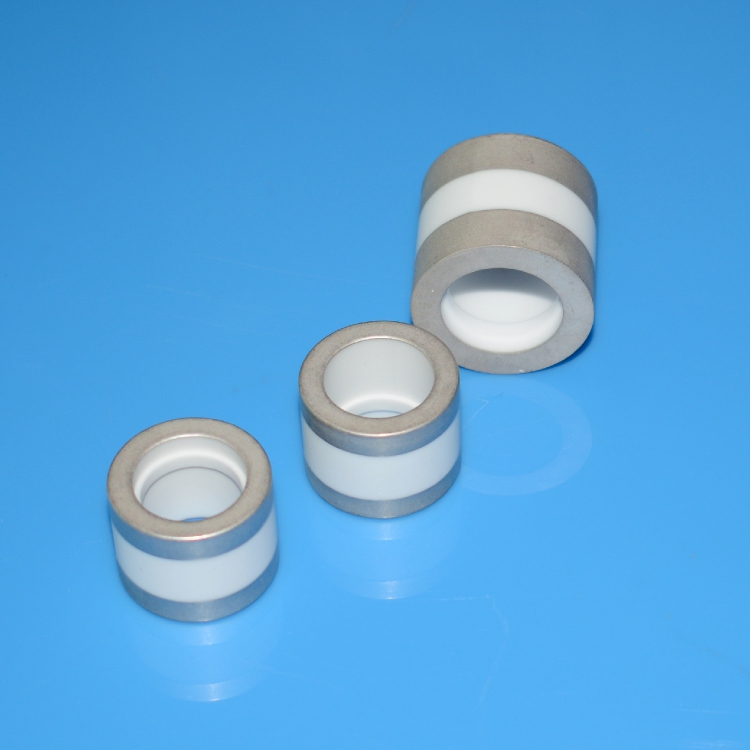

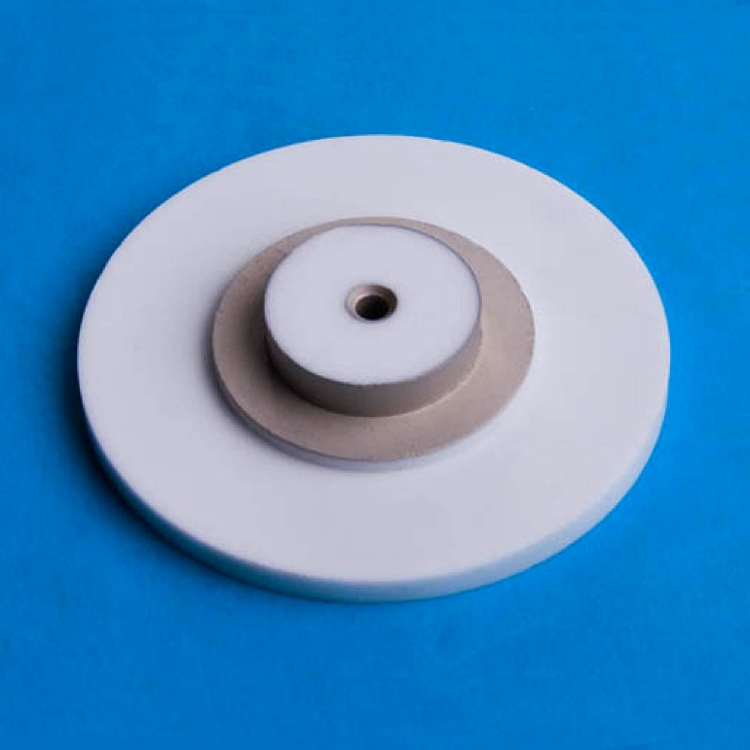

Species: Ceramic Parts

Application: Industrial Ceramic

Material: Alumina Ceramic

Processing Service: Moulding

Precision Process: Fine Grinding, Cnc Machining

Material: Alumina, Zirconia, Beryllia Optional

Metallization Type: Molybdenum, Tungsten Optional

Coating Type: Nickle, Silver, Gold Plating Optional

Color: Pure White, Pink, Red, Grayish

Thickness Of Metallization: Thickness Range From 15~40um

Thickness Of Plating: Thickness Range From 0.2~70um

Surface Finish: External Surface To Be Glazed

Application: High Voltage/High Current X-Ray Tube

Packaging: Vacumm packaging with export carton

Productivity: 50,000pcs/month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 100,000pcs/month

Certificate: RoHS

HS Code: 8547100000

Port: Shenzhen Port,Hongkong

Due to the significant difference of coefficient of thermal expansion between ceramics and metals, It's hardly impossible to bond ceramic to metal directly over in the past many years. In order to get this biggest challenges resolved, a new technology, called as "metallization of ceramics", borned. Metallization process is to deposit a thin metallic layer onto the ceramic components, it makes the surface of ceramic parts own the characteristics of metal, then achieve the brazing purpose directly from ceramic to metal.

The main types of metallization include " Molybdenum/Manganese (Mo/Mn)" and Tungsten (W), the choice of metallization depends on the outer plating. In common case, Molybdenum/Manganese will be adopted when the outer plating is nickle plating; On the other hand, Tungsten will be used when the outer plating is gold(Au) plating.

Sometimes, silver plating and copper plating would be bonded with ceramic parts directly with some advanced technology. Both metallization and metal coating thickness are always measured using XRF technology to ensure it meets the specifications.

Currently, we have been producing various Metallized ceramics, all these metallized ceramic insulators are feature with the superb strong brazing characteristics due to our unique and special paints which are developed and produced in house workshop.

Leak Rate ≤1x10-11Pa.m3/s Metal Layer Tensile Strength ≥150Mpa Volume Resistivity Insulation Strength ≥18kV/mm (D•C) Dielectric Constant 9~10(1MHz, 20°C) Cosmetic Quality:1. No cracks, no bubbles; 2. Evenly distributed glaze; 3. No contamination

≥108Ω•cm

Coefficient of Thermal Expansion

(5 ~ 8.0) × 10-6 /°C

Commonly used in x-ray tubes, Electron tubes,vacuum interrupters,Gas discharge tube, Vacuum capacitor,Vacuum thyristors, Surge arresters,Thyristor housings, Diode housings,Power grid tubes,Traveling wave tubes,Insulator rings and cylinder and so on.

1. Standardized factory with professional engineering & production team

2. A selection of shaping methods and comprehensive secondary process

3. Advanced inspection equipment and rigorous quality-control system

Q1. Can you produce customized metalized ceramic components?

A: Of course, we are able to make a variety of customized ceramic parts as per customers' specification.

Q2. Do you produce DBC Ceramic Substrate?

A: Yes, we not only make alumina metalized ceramic insulators, but also manufacture DBC & DPC ceramic substrates.

Q3. Is there any MOQ requirement?

A: Yes, there is a MOQ after samples approved, it depends on the size, the configuration, the type of coating.

Q4. How to ensure the quality?

A: Both brazing strength test and leak test will be done, then check them with XRF technology.