Min. Order:500 Piece/Pieces

Transportation:Ocean,Land,Air,Express

Port:Shenzhen Port,Hongkong

$1.5-20 /Piece/Pieces

Model No.: Customized

Brand: Jinghui ceramics

Place Of Origin: China

Types Of: Electrothermal Ceramics, High Frequency Ceramics, Dielectric Ceramics, Insulating Ceramics

Material: Zircon, Zirconia, Alumina, Zirconium Oxide, Aluminum Nitride, 96% aluminum oxide, 99% aluminum oxide

Precision Process: Fine Grinding, Cnc Machining

Metallization Type: Molybdenum, Tungsten Optional

Coating Type: Nickle, Silver, Gold Plating Optional

Color: Pure White, Pink, Red, Grayish

Thickness Of Metallization: Thickness Range From 15~40um

Thickness Of Plating: Thickness Range From 0.2~70um

Surface Finish: External Surface To Be Glazed

Application: High Voltage/High Current Feedthru

Packaging: Vacumm packaging with export carton

Productivity: 50,000pcs/month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 100,000pcs/month

Certificate: RoHS

HS Code: 8547100000

Port: Shenzhen Port,Hongkong

Metalized ceramic tube body is one of critical part in vacuum power feedthroughs, which offer unmatched dielectrical strength and outstanding mechanical strength. In the meantime, the ceramic tube could make the leakage rate low to 1*10-11 Pa.m3/s after brazing between ceramic and metal components.

They are commonly made from high purity Alumina Ceramic, such as 96% alumina, 99% alumina. They can be shaped by dry pressed, Isostatic pressed. In order to increase the electrical insulation strength and keep the surface of ceramic body away from foreign contaminations, sometimes, the Ceramic Tubes needs to be with glass glaze finish.

We can proceed with small part-size to large part-size, the min. diameter can be 1mm, the largest diameter is up to 500mm. In order to meet customers' different needs, we offer a selection of types of metallization, the typical ones as below:

1. Ceramic tube + Molybdenum (Mo/Mn) metallization ............................2. Ceramic tube + Mo/Mn metallization + Nickle(Ni) plating

3. Ceramic tube + Silver(Ag) plating..........................................................4. Ceramic tube + Tungsten (W) metallization + Gold(Au) plating

Leak Rate ≤1x10-11Pa.m3/s Metal Layer Tensile Strength ≥150Mpa Volume Resistivity Insulation Strength ≥18kV/mm (D•C) Dielectric Constant 9~10(1MHz, 20°C) Cosmetic Quality:1. No cracks, no bubbles; 2. Evenly distributed glaze; 3. No contamination

≥108Ω•cm

Coefficient of Thermal Expansion

(5 ~ 8.0) × 10-6 /°C

Widely used in vacuum interrupters, Electron tubes,Gas discharge tube, Vacuum capacitor,Vacuum thyristors, Surge arresters, Thyristor housings, Diode housings,Power grid tubes,Traveling wave tubes,Insulator rings and cylinder,X-ray tubes and so on.

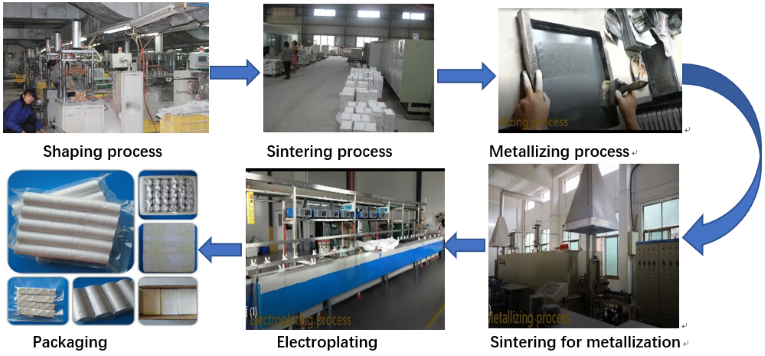

We have a complete comprehensive of production equipment for Metallized ceramics from shaping to electroplating.It helps us to make the dimensional consistency very well. Also, helping us to offer a competitive price.

Q 1. Is it available to provide customize products?

A: We could support custom-made demand as per different dimensions, design and metallization and plating.

Q 2. When can I get the price?

A: We regularly quote within 24 hours after we get your inquiry.

Q 3. How long does the whole procedure being worked out?

A: After you place an order, the manufacturing time is about 25 working days.

Q 4. What about the transportation and delivery date?

A: Normally we use Int`l express by our forwarder, or with client`s account number. It is about 3~5 working days.

Q 5. How to ensure the quality?

A: The dimension out of any batch will be carried out sampling inspection per International AQL standard. 100% cosmetic inspection will be done.