Min. Order:1000 Piece/Pieces

Transportation:Ocean,Land,Air,Express

Port:Shenzhen Port,Hongkong

Model No.: Customized

Brand: Jinghui ceramics

Place Of Origin: China

Types Of: Electrothermal Ceramics, High Frequency Ceramics, Dielectric Ceramics, Insulating Ceramics

Material: Zirconia, Alumina, Zirconium Oxide, Aluminum Nitride, Min. 94.4% Alumina

Color: White, Pink Optional

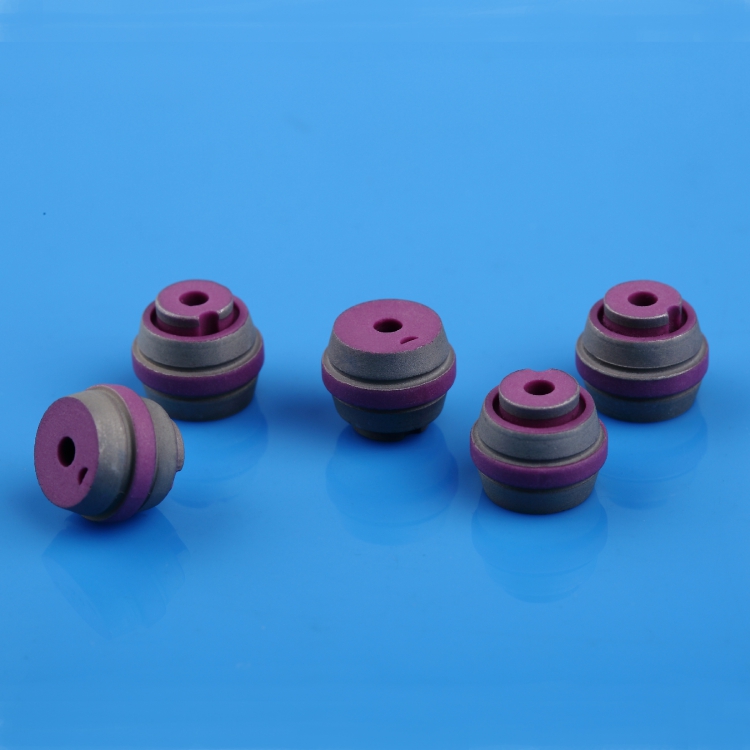

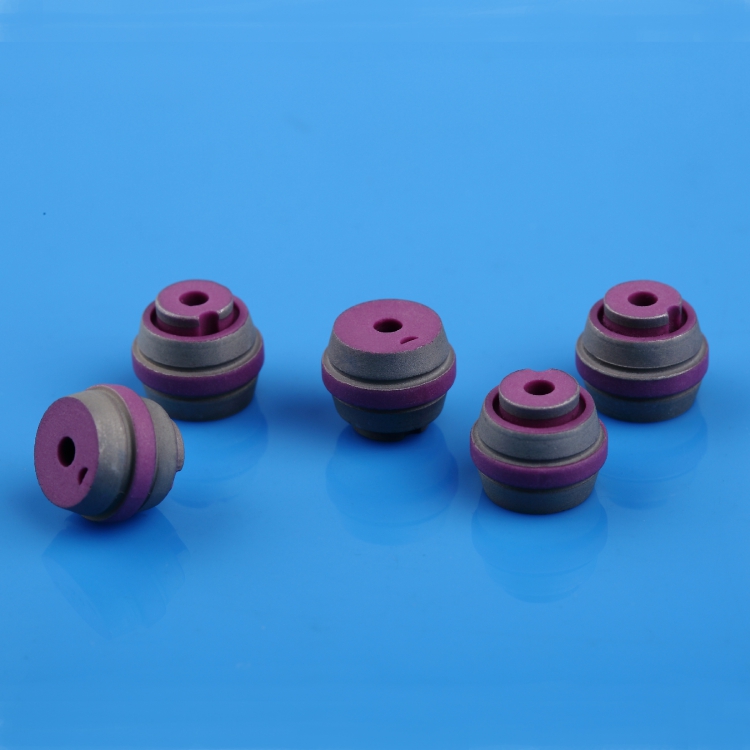

Type: Industrial Ceramic Part

Metallization Type: Mo/Mn ,W Optional

Coating Type: Nickle Plating

Thickness Of Metallization: 20~40um

Thickness Of Plating: Thin Or Thick Film Avaiable

Precision Process: Fine Grinding

Feature: High Bonding Strength With Ideal Hermercity

Application: Ceramic To Metal Jointing Technology

Packaging: Vacumm packaging with export carton

Productivity: 50,000pcs/month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 200,000pcs/month

Certificate: RoHS

HS Code: 8547100000

Port: Shenzhen Port,Hongkong

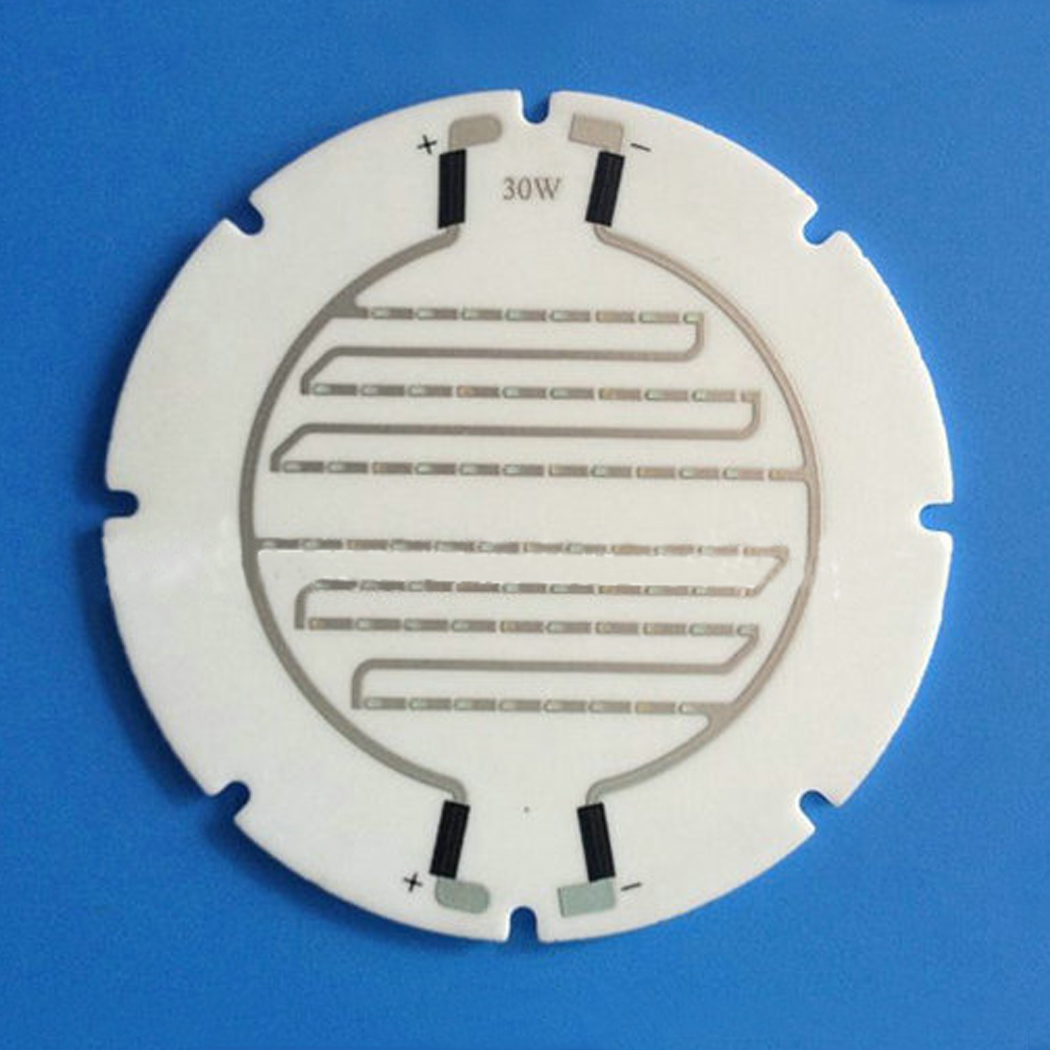

Our factory offers both thick and thin film technologies in metallizing process on the ceramic parts. The regular metallization layer is molybedenum/managnese(Mo/Mn) and Tungsten(W) as the base plating, then a nickle(Ni),gold(Au) coating will be followed onto the base layer, afterwards, the metallized ceramic part will be baked under high-temperature reduced atmosphere furnace. Finally, a metallic interface will be formed which enables ceramic to metals to be brazed directly together.

Metallized Ceramic Insulator plays a very important role in many different high vacuum devices because their remarkable electrical, mechanical and thermal properties.We are able to produce a variety of customized metallized ceramic insulators according to customers' drawing or specification.

We provide a selection of types of metallization to meet different needs from different customers,the main metallization type included as following:

1.Raw ceramic body + Mo/Mn metallization .................................... ....... 2.Raw ceramic body + Silver(Ag) plating

3.Raw ceramic body + Copper(Cu) plating................................................4.Raw ceramic body + Tin(Sn) plating

5.Raw ceramic body + Tungsten(W) metallization + Gold(Au) plating.......6.Raw ceramic body + Mo/Mn metallization + Nickle(Ni) plating

| Leak Rate | ≤1x10-11Pa.m3/s | Metal Layer Tensile Strength | ≥120Mpa |

| Volume Resistivity | ≥108Ω•cm | Coefficient of Thermal Expansion | (6.5 ~ 8.0) × 10-6 /°C |

| Insulation Strength | ≥18kV/mm (D•C) | Dielectric Constant | 9~10(1MHz, 20°C) |

| Cosmetic Quality:1. No cracks, no bubbles; 2. Evenly distributed glaze; 3. No contamination | |||

Widely used in vacuum interrupters, Electron tubes,Gas discharge tube, Vacuum capacitor,Vacuum thyristors, Surge arresters,Thyristor housings,Diode housings,Power grid tubes,Traveling wave tubes,Insulator rings and cylinder,X-ray tubes and so on

Besides, we offer various of Metallized Ceramics, like Metallized Ceramic Tube, Metallized Ceramic Substrate, Metallized Ceramic Ring, metalized ceramic disc and so on.

Q 1. Is it available to provide customize products?

A: We could support custom-made demand as per different dimensions, design and metallization and plating.

Q 2. When can I get the price?

A: We regularly quote within 24 hours after we get your inquiry.

Q 4. What about the transportation and delivery date?

A: Normally we use Int`l express by our forwarder, or with client`s account number. It is about 3~5 working days.

Q 5. How to ensure the quality?

A: The dimension out of any batch will be carried out sampling inspection per International AQL standard. 100% cosmetic inspection will be done.