Payment Type:T/T,Paypal,Western Union

Incoterm:FOB,CFR,CIF,EXW,FCA,CPT,CIP

Min. Order:500 Piece/Pieces

Transportation:Ocean,Land,Air

Port:Shenzhen,HongKong,Shanghai

$1.5≥500Piece/Pieces

Model No.: Customized

Brand: Jinghui ceramics

Packaging: Export carton

Productivity: 100,000 sets/month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 500,000 sets/month

Certificate: RoHS

HS Code: 8547100000

Port: Shenzhen,HongKong,Shanghai

Payment Type: T/T,Paypal,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

1. Material: It can be zirconia, silicon nitride and silicon carbide besides high purity alumina;

2.Shaping (forming) methods: it regularly include dry pressed, isostatic pressed and hot pressed;

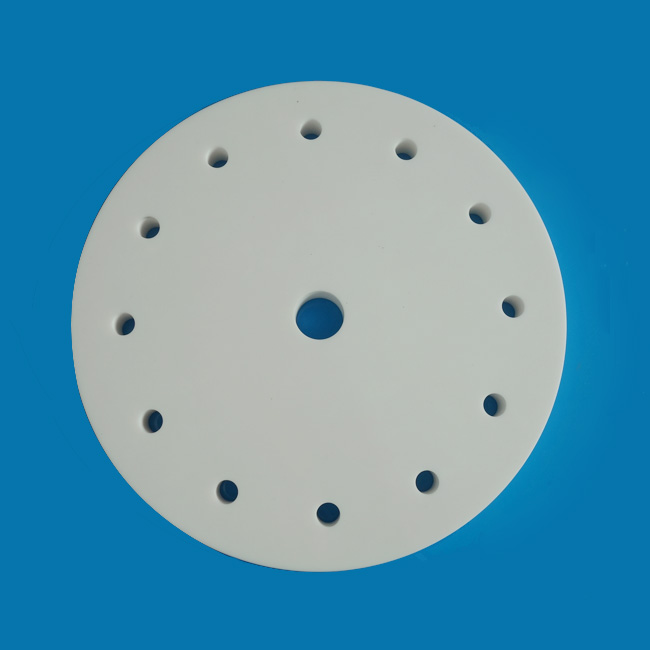

3. Available geometries: both sides can be flat, one side or double sides with concave-convex;

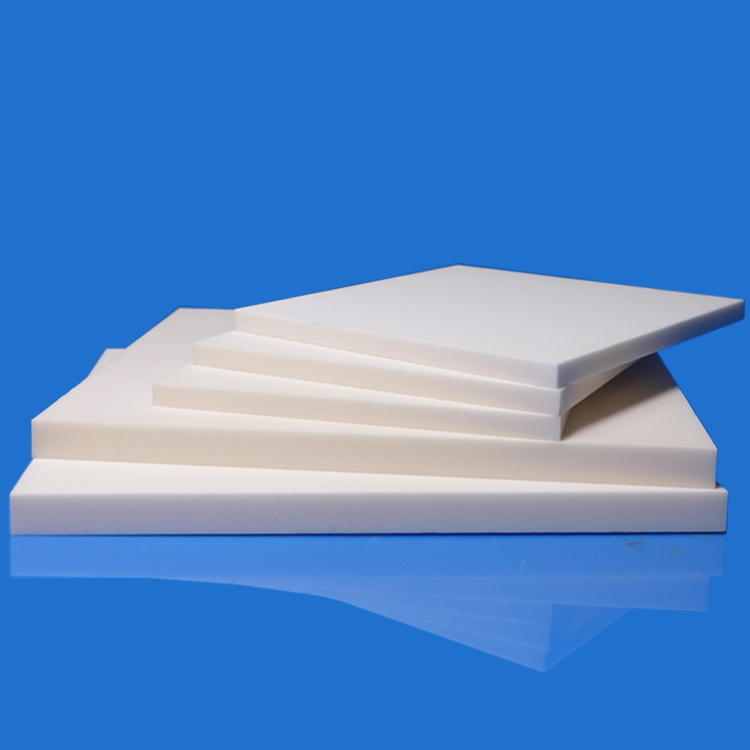

4. Dimension capability: largest side-length up to be 600mm by 500mm, min. thickness to be 0.25mm

5. Precision process: double sided grinding, lappening, tapping, drilling, grooving

6. Accurancy feasibility: flatness to be 0.005mm, tolerance can be 0.01mm or better.

7. Surface treamt: polishing, glazing, metallizing, blasting or customized surface finish

1. Good surface roughness, even if flatness of large size ceramic sheet to be 0.005mm after precision grinding

2. Good thermal shock resistance, greater than 220 T(℃) under rapid raising temperature and cooling

3. High thermal conductivity of 96% alumina, up to 24 W/m.k at 25℃, It's fit for heat insulation application

4. High dielectric strength, low dielectric constant and dielectric loss. It's an ideal material for insulation fileds.

5. High temperature resistance, the max. service temperature can be 1750℃ in the oxide condition, but up to 2200℃ in the inert atmospheres.

6. It owns excellent chemical stability, even if it can survive in most of strong acids and alkalis. Also, it's resist aging.

The Industrial Ceramic Plate is made of high purity alumina which is formed by dry pressed with very dense and smooth ceramic body. A wide range of customized shape are available, irregularly including square, rectangular, triangle, pentagonal, round, half circle and so on. We offer small size to large size alumina ceramic plate in an selection of thickness range from 0.25mm to 30mm, the max. side-length can be 600mm by 500mm. Moreover, we manufacture industrial ceramic plate in different raw materials, mainly including zirconia, silicon carbide, silicon nitride and aluminum nitride.

In addition, we also manufacture a variety of other technical ceramic components, including Metallized ceramics, high precision structural ceramic components, ceramic grinding mechanism, Pepper Mill Mechanism kit, Ceramic Seals, Ceramic Tubes . In order to meet customers' stiff application, different surface treatments and precision secondary process can be performed to reach customers' specific needs.

● Customer-orientation forever

We focus on our customers' business growth and competition, whatever, it's a small case, or large-scale demand.

● The rigorous " quality" manner and sense

Every people in the facotry do understand "No quality, no everything" and "Quality is the life of enterprises' development"

● The professional and veteran team

Our top management and senior engineers all have over 20 years of related advanced ceramic components.

● Complete and comprehensive manufacturing machines

We owns compenhensive manufacturing equipments from raw material preparation, shaping, sintering to secondary process.

Q1: Do you have capability to produce customized ceramic disc plates?

A: Yes, we support custom-made or special shape ceramic discs, typically including flat, convex and concave design.

Q2: What kinds of raw material for ceramic disc you provide?

A: Besides alumina ceramic disc, we also manufacture zirconia ceramic discs, silicon nitride disc and silicon carbide disc.

Q3: How long can I get a sample for checking the quality?

A: If we have some samples in stroage, the samples can be provided in 3 working days after receiving the inquiry from clients.

On the other hand, we will take 4~5 weeks to produce the samples as per clients specification to prepare it.

Q4. How do you ensure the quality at your site?

A: We introduced CPK value in the production line and AQL at inspection process, also sampling inspection of all batches is needed.

Q5. Are you a factory or trading company?

A: We are a direct manufacturer with complete manufacturing machines. You are welcome to visit our factory if it's available.

Q6. What other technical ceramic components do you supply?

A: We not only produce industrial ceramic plates , but also manufacturer Metalized Ceramics, Ceramic Grinding Burr,ceramic tubes, Textile Ceramics.