Min. Order:10 Piece/Pieces

Transportation:Ocean,Land,Air

Port:Shenzhen Port,Hongkong Port

$30≥10Piece/Pieces

Model No.: Standard size or customized available

Brand: Jinghui ceramics

Place Of Origin: China

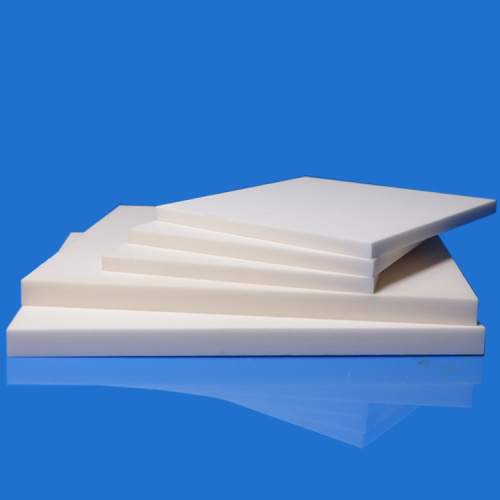

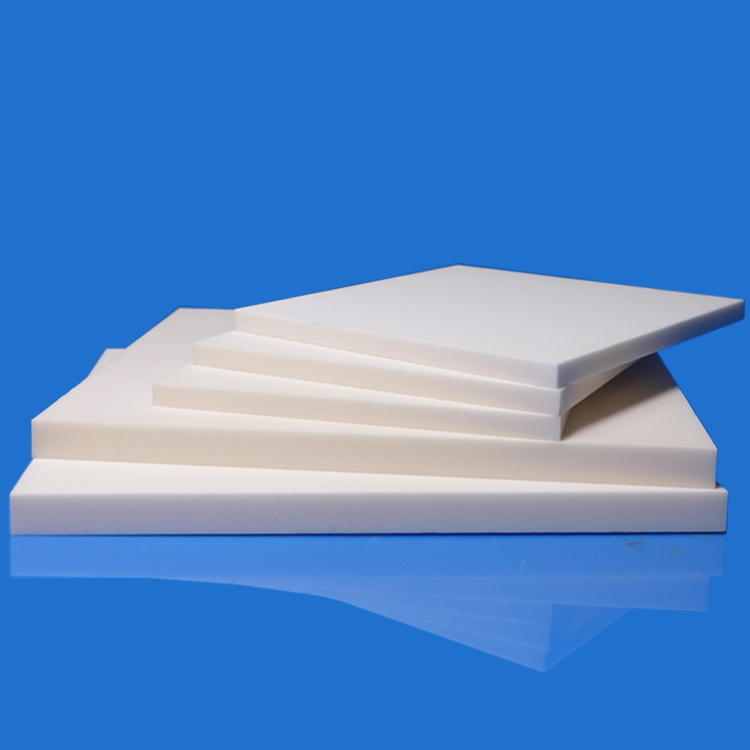

Species: Ceramic Plates

Application: Refractory

Material: Alumina Ceramic

Processing Service: Moulding

Max. Side-length: 400mm X 300mm

Product Name: Alumina Ceramic Setter Plates

Material: 99%, 99.5% Or 99.8% Alumina

Max Thickness: 300mm

Color: Ivory, Beige

Features: High-Temperature Resistant, Good Thermal Conductitivity

Application: Work As High-Temperature Ceramic Setter Plate

Packaging: Export carton

Productivity: 100,000 sets/month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 500,000 sets/month

Certificate: RoHS

HS Code: 8547100000

Port: Shenzhen Port,Hongkong Port

As setter plates, aluminum oxide ceramics offer critical advantages than traditional setters made from materials like both tungsten and graphite. They enable energy and cost-efficient processing of high-precision sintering components.

Ceramic setter plates and sintering trays help optimally arrange and secure molded parts in a sintering furnace to prevent undesirable deformations during the firing process. To ensure energy-efficient and precise process control when firing,

Our facility offers a wide range of materials made from aluminum oxide ceramics in different purities ranges from 95% to 99.8%, a selection of shaping methods will be adopted as per different thickness and dimensions, the regular forming methods are tape casting, dry-pressed and Isostatic pressed in our production, also all these ceramic setterplates can be manufactured according to customized designs and qualities with decisive advantage:

●High thermal conductivity

High thermal conductivity of Al2O3 results in homogeneous thermal distribution within the sintering components. Excellent thermal shock resistance is another added benefit, which enables faster firing cycles.

● High thermal resistance

It offers a positive effect on the energy-saving of the firing processes. Highly thermally resistant materials result in lower thicknesses of the setters, which improves energy efficiency because of less thermal ballast. In addition, ceramic setter plates can also be used at temperatures far over 1000°C.

● Surface Roughness

A desirable surface roughness ensures optimum gliding for sintered parts. The surface roughness is Ra < 1 µm makes it possible to achieve uniform shrinkage at the firing process, therefore helping to preserve the shape of the products. The smoothness of surface also protects parts from contamination from the setters.

● Chemical stability

● Optional materials: aluminum oxide ceramics, Silicon Nitride Ceramics, silicon carbon ceramics

● Dimensions : max. size up to 400mm x 300mm, max. thickness to be 30mm

● Norminal tolerance:both length and width with ± 1% of dimensions, thickness with ± 0.5 mm

● Secondary process: precisely grinding, lapping, polishing, CNC machining, glazing and metallizing

95% alumina 99.2% alumina 99.5% alumina ZrO2 (Y-TZP) Color Density g/cm3 ≥3.60 ≥3.80 ≥3.85 ≥6.0 ≥3.21 ≥4.00 3.22 Water absorption % 0 0 0 0 0 0 0 Hardness HV 1500 1700 1700 1300 2500 800 Flexural strength Mpa ≥320 ≥338 ≥379 1200 550 158 650 Compressive strength Mpa ≥2000 ≥2240 ≥2240 ≥1990 ≥3306 --- ≥2200 (Non-loading) ℃ 1500 1600 1675 850 1600 1000 1200 Thermal conductivity W/(m.K) 24 29 30 2.5 150 5 25 Ω.cm > 10^14 > 10^14 > 10^14 > 10^11 10^5 10^12 > 10^14 Insulation strength kV/mm 18 18 19 17 --- 3.93 16 Dielectric constant - 9.5 9.5 9.7 29 --- 9.5 8.2

Property Unit SiC TiO2 Si3N4 White Ivory Ivory White Black Black Gray Max. service temperature

Volume resistivity

1. Owns in-house comprehensive types of manufacturing equipment from raw material preparation to secondary processes machines.

2. With over 13 years manufacturing experience of OEM, ODM and professional, trusted and responsible team members.

3. Rigorous and complete quality control system, including IQC, IPQC, OQC according to ISO quality management system.

4. Support special and custom-made needs, no matter what is prototyping and R&D cases, or serial massive demands for cost down.

5. Offering many selection of technical ceramic materials, including alumina, zirconia, silicon carbide, steatite, mullite, silicon carbide

6. We are dealing with every case in order to enhance the competition of customers, and make their business growth.

7. Provinding one-stop ceramic components, including Ceramic Tubes, Ceramic Rods, Industrial Ceramic Plate, various ceramic insulators.

Q1: What kinds of raw material for ceramic setter plates you provide?

A: Besides alumina ceramics, we also manufacture ceramic setter plates in both silicon nitride and silicon carbide.

Q2: Do you have capability to produce customized ceramic setter plates?

A: Yes, we support custom-made or special shape ceramic setter plates, typically including flat setters, convex setters.

Q3: How long can I get a sample for checking the quality?

A: If we have some samples in stroage, the samples can be provided in 3 working days after receiving the inquiry from clients.

On the other hand, we will take 4~5 weeks to produce the samples as per clients specification to prepare it.

Q4. How do you ensure the quality at your site?

A: We introduced CPK value in the production line and AQL at inspection process, also sampling inspection of all batches is needed.

Q5. What other technical ceramic components do you supply?

A: We not only produce al2o3 ceramic setter plate, but also manufacturer Metalized Ceramics, Ceramic Grinder, Ceramic Seals.