Payment Type:T/T,Paypal,Money Gram,Western Union

Incoterm:FOB,CIF,FCA

Min. Order:500 Piece/Pieces

Transportation:Ocean,Land,Air

Port:Shenzhen Port,Hongkong Port

Model No.: Customized

Brand: Jinghui ceramics

Packaging: Export carton

Productivity: 100,000 sets/month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 500,000 sets/month

Certificate: RoHS

Port: Shenzhen Port,Hongkong Port

Payment Type: T/T,Paypal,Money Gram,Western Union

Incoterm: FOB,CIF,FCA

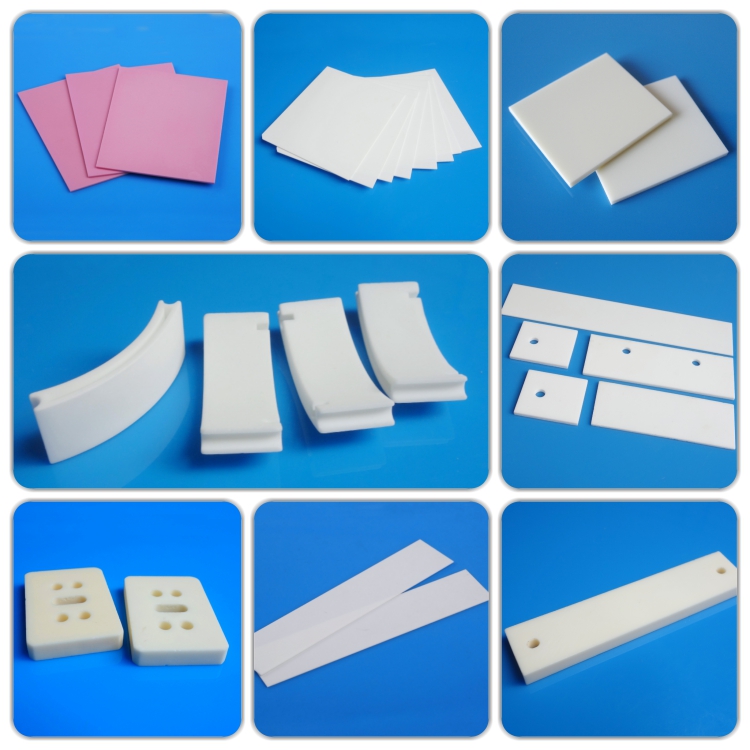

Due to alumina's high thermal conductivity, heat dissipation and exceptional insulation properties, in the meantime, it has outstanding wear resistance, greater hardness than almost all metal parts and lower density, it's extensively used as ceramic thermal plate in varity of electrical and electronic devices.

Other prime features:

1. High termperature resistance

2. High voltage/currency resistance

3.Anti-corrosion with more longer service life

4.Exceptional electrical insulation

5. EMI and antistatic

Typical application:

-Power electronic devices

-Communication devices

-High power transistor module substrate

-High-density hybrid circuits

-Microwave power devices,

-Power semiconductor devices,

-Power electronic devices,

-Optoelectronic components,

-Laser-semi-conductor,

-High power LED lights,

-IC products

Products showroom

Technical Data. sheet

95% alumina 99.2% alumina 99.5% alumina ZrO2 (Y-TZP)

Items Unit SiC TiO2 AlN Color White Ivory Ivory White Black Black White Density g/cm3 ≥3.60 ≥3.80 ≥3.85 ≥6.0 ≥3.21 ≥4.00 3.3 Water absorption % 0 0 0 0 0 0 0 Hardness HV 1500 1700 1700 1300 2500 800 Flexural strength Mpa ≥320 ≥338 ≥379 1200 550 158 450 Compressive strength Mpa ≥2000 ≥2240 ≥2240 ≥1990 ≥3306 --- ≥2200 Max. service temperature

(Non-loading) ℃ 1550 1600 1675 850 1600 1000 1200 Thermal conductivity W/(m.K) 24 29 30 2.5 150 5 170 Volume

resistivity Ω.cm > 10^14 > 10^14 > 10^14 > 10^11 10^5 10^12 > 10^14 Insulation strength kV/mm 18 18 19 17 --- 3.93 17 Dielectric constant - 9.5 9.5 9.7 29 --- 95 8.9

Company profile

We, at Jinghui Industry Ltd is a leading advanced ceramic components' manufacturer in China over than 12 years. Currently, our main products include Metallized ceramics, ceramic grinders for pepper/spice/salt/herb/coffee mill, Ceramic Substrate / plate/ sheet/ wafer, ceramic tube/bushing/sleeve/rod, Zirconia Ceramic Components, engineering / structure ceramic components, ceramic seal components and so on.

The selection manufacturing methods include dry pressing, hot pressing, isostatic pressing, ceramic injection molding, extrusion with selection of materials. Also we have our own comprehensive high precison processing and firing production line. Such as metallizing, glazing, fine grinding, CNC machining, laser cutting and so on.

The quality products come from art of state of manufacturing processes, also it's in need of advanced inspection tool. The main inspection equipment include CMM, projector etc.

With our reliable products, professional service and good credit established with customers, we have been exporting our products to Europe, North American, Asia, South American, South African over than 50 countries.

Our strength

FAQ:

Q1. Is it available to provide customize products?

A: We always support custom-made ceramic substrate, ceramic plate, ceramic wafer, ceramic sheet as per different dimensions, design and shape.

Q2. When can I get the price?

A: We regularly quote within 24 hours after we get your inquiry. If you are in urgent need of get the price, please call us or tell us in your email so that we will proceed your inquiry as priority.

Q3. How long can I expect to get the sample?

A: After you pay the sample charge and send us confirmed files, the samples will be ready for delivery in 4 weeks. The samples will be sent to you via express and arrive in 3-5 workdays. You can use your own express account or prepay us if you do not have an account.

Q4. How long does the whole procedure being worked out?

A: After you place an order, the manufacturing time is about 25 working days.

Q5. What about the transportation and delivery date?

A: Normally we use Int`l express by our forwarder, or with client`s account number. It is about 3~5 working days. For some heavy goods, sea freight will be recommended, it will take around 1 month, but It also depends on where you are.

Q6. How to ensure the quality?

A: The dimension out of any batch will be carried out sampling inspection per International AQL standard. 100% cosmetic inspection will be done.

Q7. Are you a factory or trading company?

A: We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Contact Us