Payment Type:T/T,Paypal,Money Gram,Western Union

Incoterm:FOB,CFR,CIF,EXW,FCA,CPT,CIP

Min. Order:10 Piece/Pieces

Transportation:Ocean,Land,Air

Port:Shenzhen Port,HongKong Port

$2010-99Piece/Pieces

$15100-499Piece/Pieces

$12≥500Piece/Pieces

Model No.: Customized

Brand: Jinghui ceramics

Packaging: Vacumm packaging with export carton

Productivity: 100000 pcs/month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 200,000pcs/month

Certificate: RoHS, REACH

HS Code: 8547100000

Port: Shenzhen Port,HongKong Port

Payment Type: T/T,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

| Purity | over 99% |

| Max. dimensions available | OD to be 300mm, length to be 400mm |

| The grade of tolerance | General tolerance: 1% of the dimensions, 0.01mm after grinding |

| Surface treatment | Lapping, fine grinding and polishing |

Boron Nitride material has high thermal stability, chemical stability and electrical insulation, but also has a high thermal conductivity, dielectric properties, and easy processing products and so on. Its melting point up to 2800 ℃, is a typical electrical insulator, but also an excellent thermal conductor.

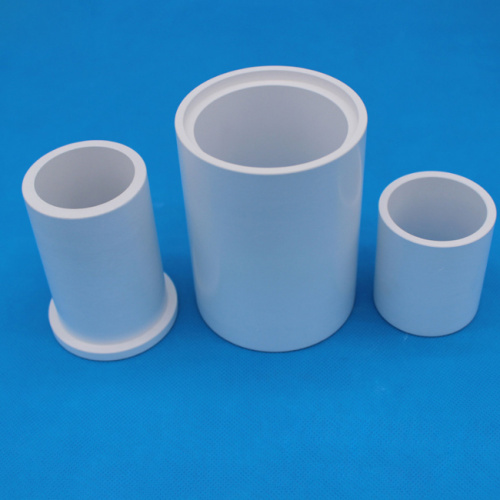

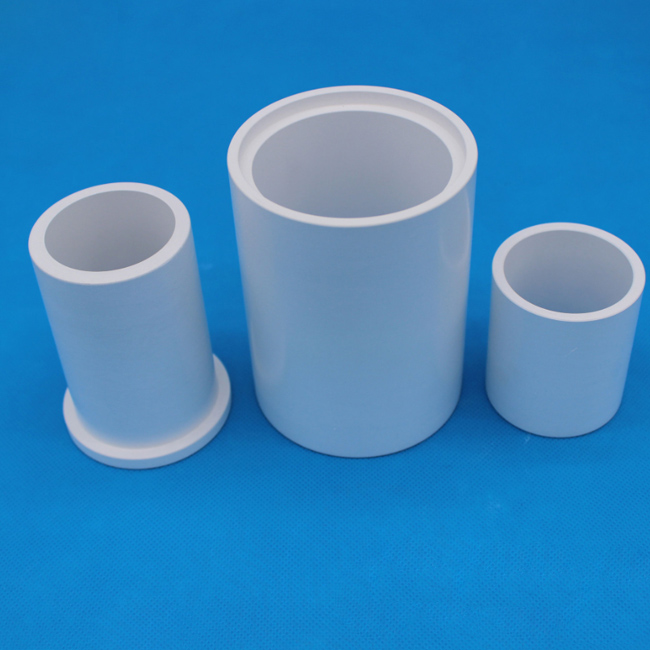

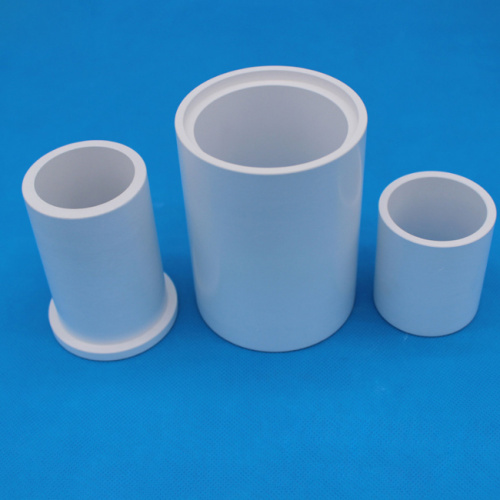

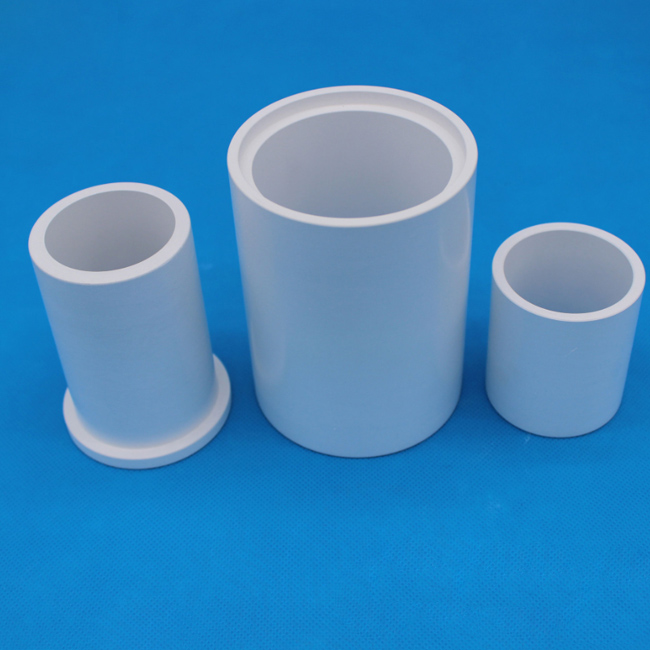

We have been manufacturing various of boron nitride ceramic parts, including Boron nitride ceramic crucibles, Boron nitride ceramic setters, Boron nitride ceramic plates, Boron nitride Ceramic Rods, Boron nitride ceramic bushing and so on.

Boron nitride ceramic parts widely used as ceramic insulators for high-temperature furnaces, side dams in thin-strip casting process, crucibles and containers for molten metals and break rings in horizontal continuous casting.

| Property | Unit | Value |

| Density | g/cm3 | >2 |

| Rich Hardness | HL | 300 |

| Flextural Strength | Mpa | 35 |

| Coefficient of thermal expansion (25~1200℃) | 10^-6/K | 1~2 |

| Thermal Conductivity at 20℃ | W/mK | 35 |

| Max. Service Temperature | Air | 900℃ |

| Vacuum | 1800℃ | |

| Inert | 2200℃ | |

| RT Resistivity | Ω.cm | over 10^14 |

1. Over 20,000 square meters manufacturing workshop.We have in-house art-of-the-state comprehensive manufacturing equipment, including grinding & mixing machines for material preparation, selection of shaping machines, sintering furnace, fine grinding machines, CNC machines, surface treatment production line ( polishing, glazing, metalizing) and electroplating production line.

2. We strictly perform the management quality system per ISO9001: 2015 and all departments of IQC, IPQC, OQC have veteran and professional staffs. Every pieces flow to the customers have been inspected rigorously.

3. Cost - effective is another focus in our facility, we pay special attention to every details beginning from purchasing material to shipping and thinking of how to reduce the cost prior to ensuring the quality.