Payment Type:T/T,Paypal,Western Union

Incoterm:FOB,CFR,CIF,EXW,FCA,CPT,CIP

Min. Order:100 Piece/Pieces

Transportation:Ocean,Land,Air

Port:Shenzhen Port,HK Port

$2100-999Piece/Pieces

$1.251000-4999Piece/Pieces

$1.155000-9999Piece/Pieces

$1.05≥10000Piece/Pieces

Model No.: Customized

Brand: Jinghui ceramics

Place Of Origin: China

Types Of: Electrothermal Ceramics, High Frequency Ceramics, Dielectric Ceramics, Insulating Ceramics

Material: Alumina

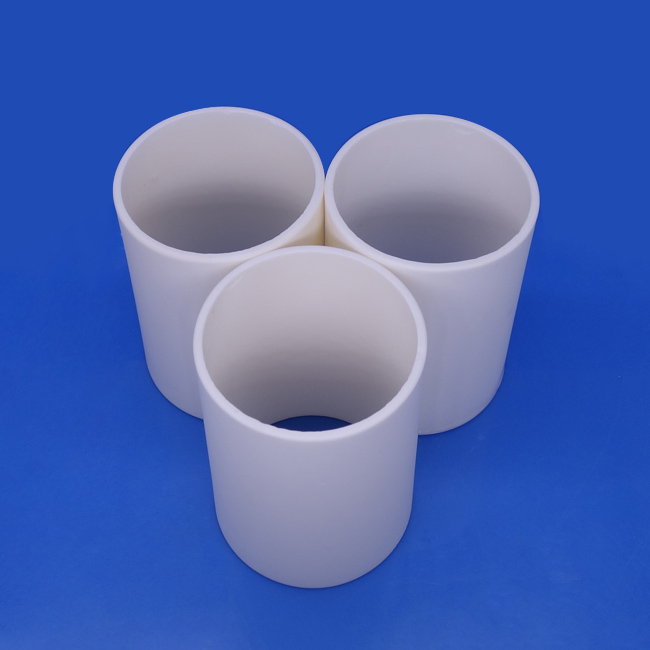

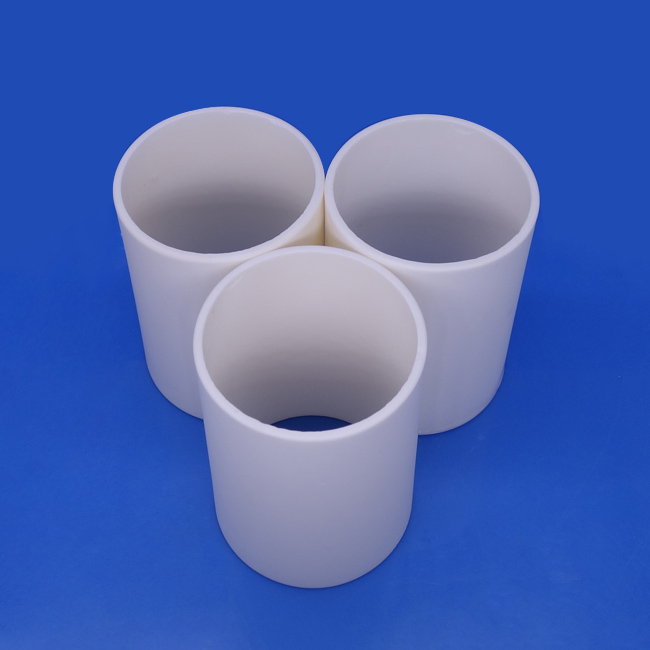

Product Name: 99% Alumina

Forming Method: Dry Pressed

Density: Over 3.80g/Cm3

Appearance: Without Contamination, Free Of Pinholes

Secondary Process: Diamond-Like Fine Grinding

Certificate: Fda, Lfgb, Rohs

Usage: Ceramic Protection Tube For Food Industry

Packaging: Export carton

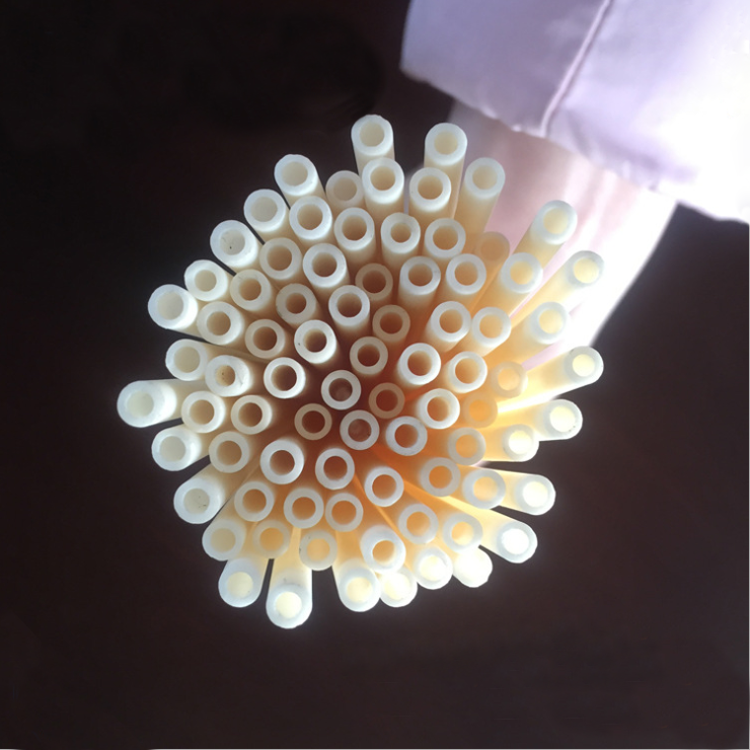

Productivity: 100,000 sets/month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 500,000 sets/month

Certificate: RoHS

HS Code: 6914100000

Port: Shenzhen Port,HK Port

Payment Type: T/T,Paypal,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

Alumina (Al2O3) is a superb hard, chemically resistant material and has the ability to withstand very high temperatures in aggressive environments. Our facility offers alumina with various purity levels which ranges from 75% to 99.8%. The level of purity, grain size, and density required is dependent on the rigors of the application and the component configuration.

Currently, we have been supplying a broad range of ceramic tube, inclding different design, different specification, different surface treatment and so on. All these ceramic tube can be machined at our own factory to cater to customers' specific needs.

1. Forming methods: dry pressed, hot pressed, extrusion, ceramic Injection molding, Isostatic pressed

2. Material options: alumina ( purity range from 95% to 99.8%), zirconia,silicon nitride, boron nitride

3. Dimension capability: the min. inner diameter can be 1mm, the max. outer diameter up to be 800mm

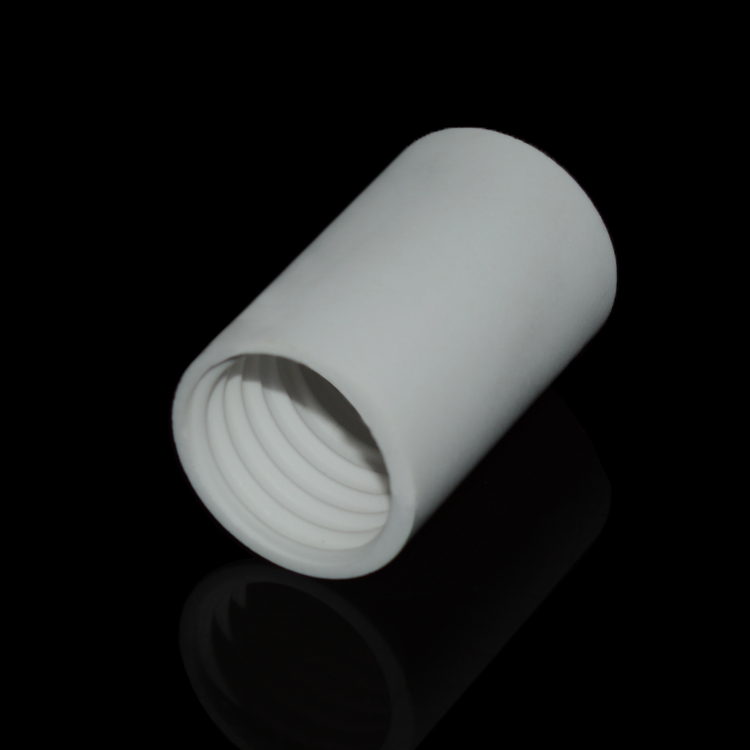

4. Available design: both ends open, one end closed, multiply holes, side-slot, steps, threaded, half tubes.

5. Secondary processing: CNC machining, lapping, grinding, drilling, threaded,precision cutting and so on

6. Tolerance: outer diameter can be 0.005mm, inner diameter can be 0.01mm, overall length can be 0.01mm

7. Surface treatment: external and internal surface to be lappend, polished, glazed or metallized

1. High temperature resistance, it can withstand up to 1750℃ in the air condition, but up to 2200℃ in vacuum atmosphere

2. Outstanding wear resistance, over 276 times in comparison with stainless steel

3. Exceptional corrosion resistance, it can withstand various strong acid and alkali, like HF, H2SO4

4. Extraordinary electrical insulation, it always use in many high voltage, high-current application

5. Great mechanical properties, hardness, compressive and flexural strength are much higher stainless steel

Remark:

We are able to achieve a variety of special requirement of Ceramic Tubes, including different materials,

different designs, different geometries.

Gerneral

Property

Units

99.5% al2o3 99.2% al2o3 95% al2o3 Mechanical

Density

g/cm3

≥3.90

≥3.85

≥3.65

Water absorption

%

0

0

0

Hardness

HV

1700

1700

1500

Flexural strength

Mpa

≥379

≥338

≥320

Compressive strength

Mpa

≥2240

≥2240

≥2000

Fracture toughness

Mpam^1/2

4-5

4-5

3~4 Thermal

Max. service temperature

(Non-loading)

℃

1700

1600

1500 CTE (20-800℃)

1×10 -6 /℃

6.5~8.0

6.2~8.0

5.0~8.0

Thermal shock

T(℃)

≥250

≥220

≥200

Thermal conductivity

W/m.k

30 29 24 Specific heat

1 x 10^3 J/(kg·K)

0.78

0.78

0.78

Electrical

Volume resistivity

25℃

ohm.cm

>1 x 10^14

>1 x 10^14

>1 x 10^14

300℃

1 x 10^12

8 x 10^11

10 ^12 -10^13

500℃

5 x 10^10

2 x 10^ 9

1 x 10^9

Insulation strength

KV/mm

19

18 18 Dielectric constant (1Mhz)

(E)

9.7

9.5 9.5

Q2. When can I get the price after sending the inquiry?

A: We regularly quote within 24 hours after we get your inquiry. If you are in urgent need of getting the price,

please call us or tell us in your email so that we will proceed with your inquiry as a priority.

Q3. How to ensure quality in your factory?

A: The strict quality-control will be done in the production line, including IQC, IPQC, QA, OQC,

also both CKP, AQL are regularly used in the production.

Q4. Are you a factory or trading company?

A: We are a professional manufacturer. You are welcome to visit our factory and cooperate with us.

Q5.Can you produce other technical ceramic parts?

A: We also focus on producing Metalized Ceramics, Industrial Ceramic Plate, Ceramic Seals and Textile Ceramics.