Payment Type:T/T,Paypal,Western Union

Incoterm:FOB,CFR,CIF,EXW,FCA,CPT,CIP

Min. Order:500 Piece/Pieces

Transportation:Ocean,Land,Air

Port:Shenzhen Port,HK Port

Brand: Jinghui ceramics

Packaging: Export carton

Productivity: 100,000 sets/month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 500,000 sets/month

Certificate: RoHS

HS Code: 6914100000

Port: Shenzhen Port,HK Port

Payment Type: T/T,Paypal,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

2. Material options: different purity alumina, zirconia, Silicon carbide, Silicon nitride and Aluminum nitride

3. Dimension capability: Min. the inner diameter can be 1mm, Max. the outer diameter can be 800mm

4. Secondary processing: CNC machining, lapping, grinding, drilling, threaded,precision cutting and so on

5. Tolerance: outer diameter can be 0.005mm, inner diameter can be 0.01mm, overall length can be 0.01mm

6. Surface treatment: External and internal surface to be lappend, polished, glazed or metallized

2. Great mechanical properties, hardness, compressive and flexural strength are much higher stainless steel

3. Exceptional corrosion resistance, it can withstand various strong acid and alkali, like HF, H2SO4

4. Extraordinary electrical insulation, it always use in many high voltage, high-current application

Alumina or aluminum oxide (al2o3) in its various of different grade has most extensively application than other technical ceramic materials. Alumina possesses higher hardness, super wear resistance, high compressive strength, high temerpatrue resistance, chemical stability and high electrical insulation,as well as the cost performance advantage. As with the purity increases, both wear resistance and corrosion resistance also increases, so alumina are grouped together based on purity levels, including 75% alumina, 85% alumina, 90% alumina, 95% alumina, 99% alumina, 99.5% alumina, 99.8% alumina, 99.9% alumina.

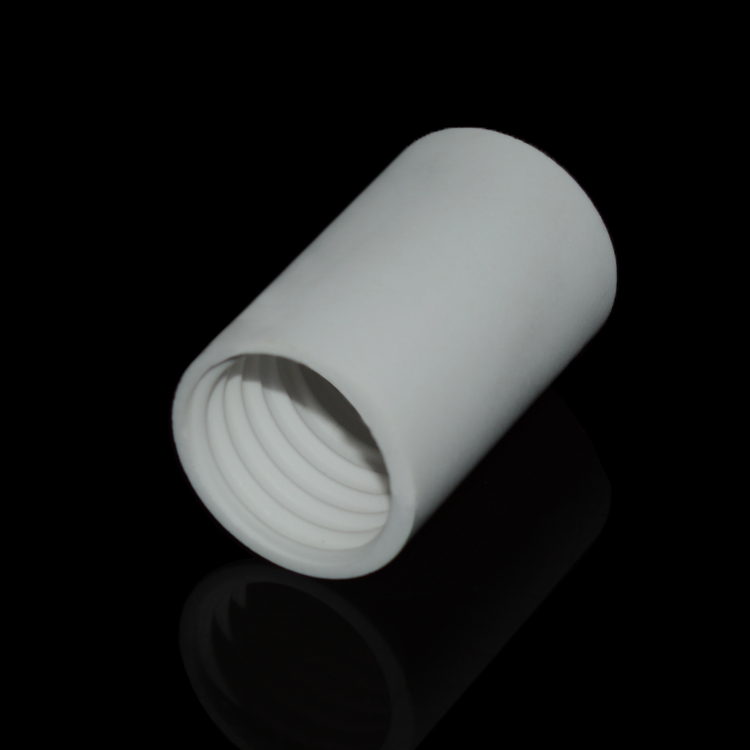

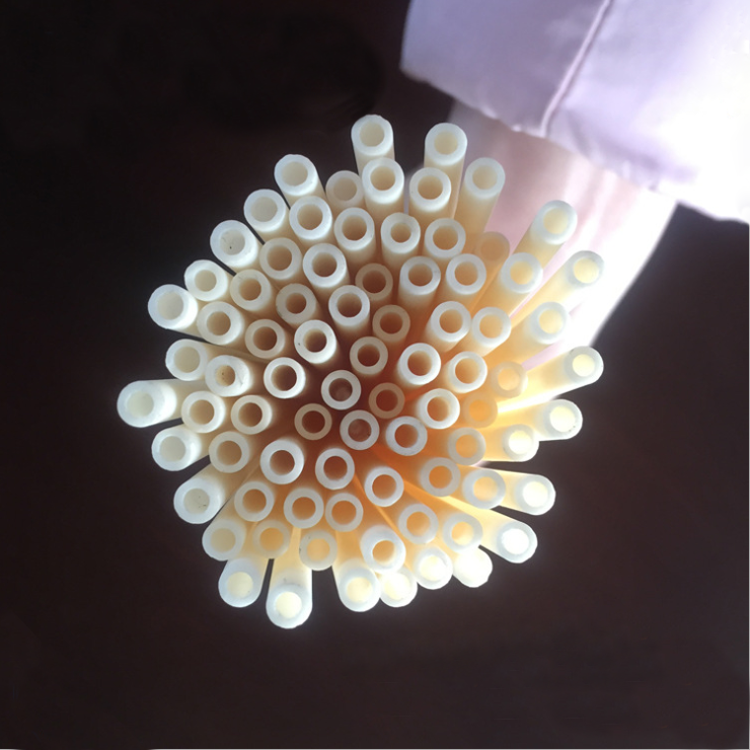

Alumina Ceramic Tubes generally used as a kind of standard protection part, so our facility has many selections of stocks. Our vast, readily-available inventory allows us to supply our customer’s ceramic tube needs immediately, even for hard-to-find or specialty products. Except for standard design both ends open ceramic tube, we also produce one end closed ceramic tube, square, rectangular, hex, double-bores, tri-bores tube.

Aluminas are used in a variety of general-purpose applications, and their grade is chosen based on the application environment. Additionally, different purity alumina can be formulated in our factory if needed for more demand applications

Remark:

We are able to achieve a variety of special requirement of ceramic tubes, including different materials,

different designs, different geometries.

Gerneral

Property

Units

99.5% al2o3 99.2% al2o3 95% al2o3 Mechanical

Density

g/cm3

≥3.90

≥3.85

≥3.65

Water absorption

%

0

0

0

Hardness

HV

1700

1700

1500

Flexural strength

Mpa

≥379

≥338

≥320

Compressive strength

Mpa

≥2240

≥2240

≥2000

Fracture toughness

Mpam^1/2

4-5

4-5

3~4 Thermal

Max. service temperature

(Non-loading)

℃

1700

1600

1500 CTE (20-800℃)

1×10 -6 /℃

6.5~8.0

6.2~8.0

5.0~8.0

Thermal shock

T(℃)

≥250

≥220

≥200

Thermal conductivity

W/m.k

30 29 24 Specific heat

1 x 10^3 J/(kg·K)

0.78

0.78

0.78

Electrical

Volume resistivity

25℃

ohm.cm

>1 x 10^14

>1 x 10^14

>1 x 10^14

300℃

1 x 10^12

8 x 10^11

10 ^12 -10^13

500℃

5 x 10^10

2 x 10^ 9

1 x 10^9

Insulation strength

KV/mm

19

18 18 Dielectric constant (1Mhz)

(E)

9.7

9.5 9.5

Q2. When can I get the price after sending the inquiry?

A: We regularly quote within 24 hours after we get your inquiry. If you are in urgent need of getting the price,

please call us or tell us in your email so that we will proceed with your inquiry as a priority.

Q3. How to ensure quality in your factory?

A: The strict quality-control will be done in the production line, including IQC, IPQC, QA, OQC,

also both CKP, AQL are regularly used in the production.

Q4. Are you a factory or trading company?

A: We are a professional manufacturer. You are welcome to visit our factory and cooperate with us.

Q5.Can you produce other technical ceramic parts?

A: We also focus on producing Metalized Ceramics, Industrial Ceramic Plate, Ceramic Seals and Textile Ceramics.