Payment Type:T/T,Paypal,Money Gram,Western Union

Incoterm:FOB,CFR,CIF,EXW,FCA,CPT,CIP

Min. Order:1 Piece/Pieces

Transportation:Ocean,Land,Air

Port:Shenzhen,HongKong

$651-99Piece/Pieces

$52100-999Piece/Pieces

$49≥1000Piece/Pieces

Model No.: Standard

Brand: Jinghui ceramics

Material: Silicon Nitride

Packaging: Export carton

Productivity: 100000 pieces/month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 50000 pieces/month

Certificate: RoHS

HS Code: 8547100000

Port: Shenzhen,HongKong

Payment Type: T/T,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

The specification of the silicon nitride Ceramic Substrate

1. Raw material: Silicon Nitride Ceramics

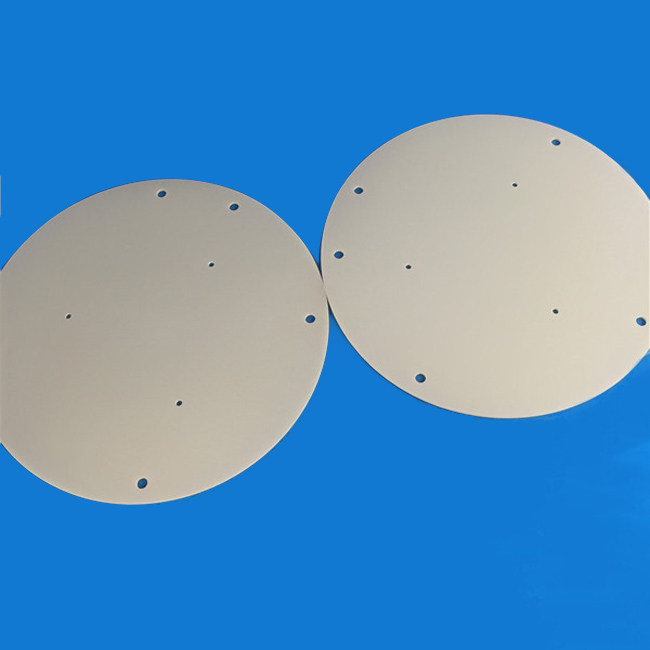

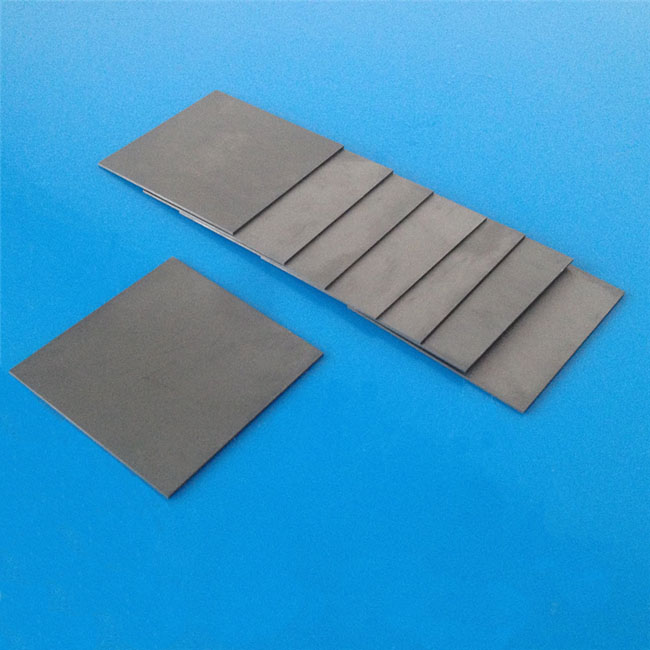

2. Appearance: grey colour without any crack and contamination

3. Standard size: 190mm x 140mm,

4. The standard thickness of substrate : 0.25mm, 0.32mm, 0.635mm.

5. Surface roughness: to be Ra0.3 ~ 0.6

The main features of the silicon nitride ceramic substrate

1. The thermal conductivity is more than 80 W/m.K

2. It resists high temperature thermal shock up to 1000℃

3. The mechanical strength and hardness of AlN base after sintering is much higher than tape casting and dry pressed

4. High-temperature resistance and chemical stability, it will not be corroded by melting metal or acid.

5. It offers very high purity up to 99%, also it's free of toxicity and meets RoHS, REACH regulation

The description of the silicon nitride ceramic substrate

The High-strength and high-thermal-conductivity silicon nitride ceramic substrate, its bending strength is 2-3 times that of aluminum nitride ceramic substrate, which can improve the strength and impact resistance of silicon nitride ceramic copper clad laminates, and weld thicker oxygen-free copper without producing The phenomenon of ceramic cracking improves the reliability of the substrate; by covering with a thick copper substrate, its thermal conductivity is 3-4 times that of the Alumina Ceramic Substrate, which greatly improves the heat dissipation performance of the substrate; the substrate has a stronger current carrying capacity and the overall substrate The heat dissipation performance is better, the thermal resistance is lower, and the temperature shock resistance is stronger.

Application Scope Silicon nitride ceramic substrate has the characteristics of high strength, high thermal conductivity, and high reliability. It can be used to make circuits on the surface by wet etching process. After surface plating, it is a kind of high reliability electronic substrate module packaging Substrate material is the preferred substrate material for 1681 power control modules for new electric vehicles. In addition, the ceramic substrate industry also involves technology in many fields such as LED, fine ceramic preparation, thin film metallization, yellow light lithography, laser forming, electrochemical plating, optical simulation, microelectronic welding, etc. The products include power transmitters, photovoltaic devices, and IGBT modules. , Power-type thyristors, resonator bases, semiconductor packaging substrates and other high-power optoelectronics and semiconductor devices have a wide range of uses.

Remark:

We supply a broad range of ceramic base, including Alumina Ceramic base, zirconia ceramic base,

silicon nitride ceramic base, aluminum nitride ceramic base and so on.

General

Properties

Unit

Value

Mechanical

Purity

% ≥99

Volume Density

g/cm3

≥3.28

Color

Grey Porosity

% 0 Compressive Strength

MPa - Bending Strength

MPa 800 Elastic Modulus

MPa 330 Fracture toughness

Mpam1/2 3

Thermal

Max. service temperature (Non-loading)

℃

1800 Thermal Conductivity (25℃)

W/m.k

≥80

Coefficient of Thermal Expansion (CTE)

1*10-6 m/k

4.6 Specific heat

1 x 103J/(kg·K)

0.74 Electrical

Volume Resistivity (25℃)

ohm.cm

1*1014

Insulation Breakdown

KV/mm

25 Dielectric constant (1Mhz)

(E)

8.7

1. Vacuum Hot Pressed Sintering Furnace

2. High Precision Machining Capability

3. CNC machining Workshop

4. Customized capability from small size to big-size

Remark:

We have own in-house comprehensive types of manufacturing equipment, including forming machines,

vacuum sintering furnace, High precision machining equipment, polishing machines, metalizing production lines.

1. High Precision Inspection Tools

2. OQC Inspection Workshop

Remark:

1. We have complete and rigorous quality-control system, including IQC, IPQC, QA and OQC per ISO9001.

2. We also have professional quality assurance team and precision inspection equipments for quality-control.

FAQs (Frequently Asked Questions)

Q1. When can I get the price?

A: We regularly quote within 24 hours after we get your inquiry. If you are in urgent need of get the price,

please call us or tell us in your email so that we will proceed your inquiry as priority.

Q2:Is it available to provide customized products?A: We always support custom-made demand as per different dimensions, design and surface treatment.

Q3. How long can I expect to get the sample?

A: After you pay the sample charge and send us the confirmed files, the samples will be ready for delivery in 4 weeks.

Q4:How long does the whole procedure being worked out?

A: After you place an order, the manufacturing time is about 25 working days.

Q5. Are you a factory or trading company?

A: We are a professional manufacturer. You are welcome to visit our factory.