Payment Type:T/T,Paypal,Money Gram,Western Union

Incoterm:FOB,CFR,CIF,EXW,FCA,CPT,CIP

Min. Order:500 Set/Sets

Transportation:Ocean,Land,Air

Port:Shenzhen Port,Hongkong Port

Model No.: Customized

Brand: Jinghui ceramics

Packaging: Export carton

Productivity: 100,000 sets/month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 500,000 sets/month

Certificate: RoHS

Port: Shenzhen Port,Hongkong Port

Payment Type: T/T,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

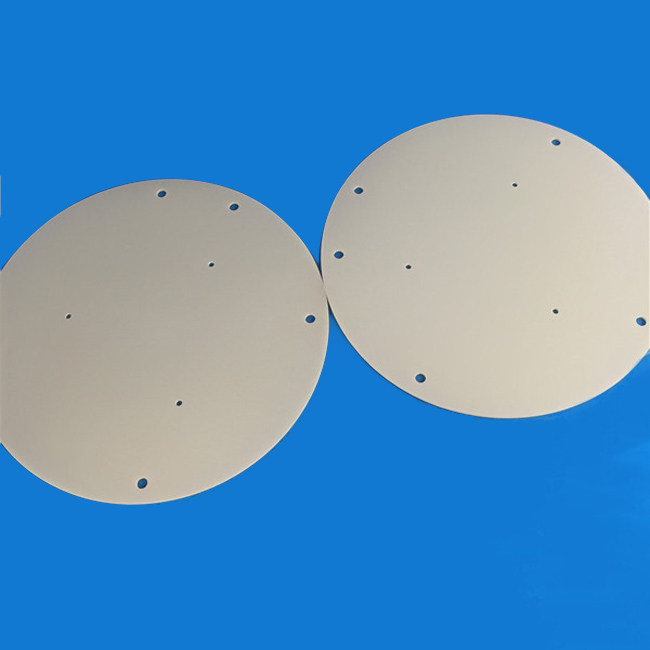

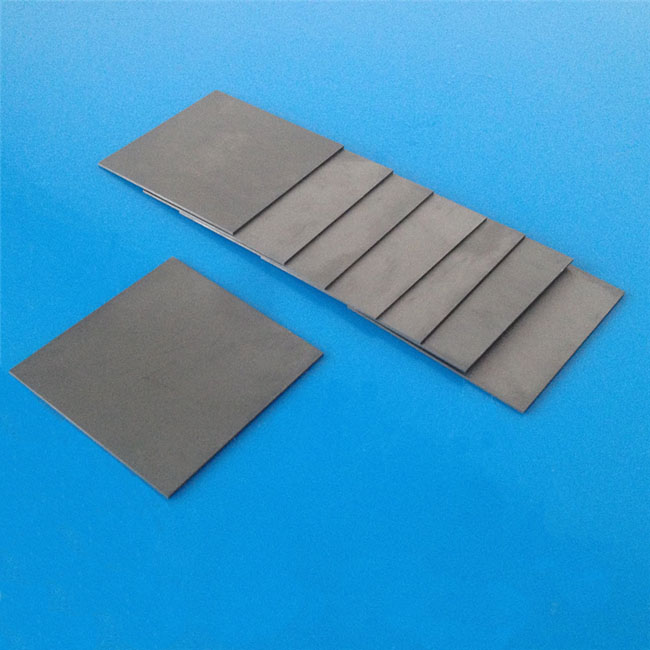

Ceramic wafers are used in many electronic applications where a thin insulating laer of thermally stable material is required to conduct heat away from electronic components whilst electrically insulating them, and the main material is zirconium oxide ceramics and different grade alumina from 95% to 99.7% alumina.We have been supplying many diversity of ceramic wafers from 0.2mm to 1.0mm thick with fine secondary processings, like fine polishing, precision grinding, laser cutting and so on.

Properties with excllent insulation, high mechanical strength, high thermal conductivity, low expansion cofeeicient, small dielectric constant, high temperature resistance, chemistry resistance and excllent wear resistance and good thermal shock from heat to cold.

Remark:

We focus on producing various ceramic wafer, including Alumina Ceramic wafer, zirconia ceramic wafer,

aluminum oxide ceramic wafer and silicon nitride ceramic wafer.

95% alumina 99.2% alumina 99.5% alumina ZrO2 (3Y-TZP)

Items Unit SiC TiO2 Si3N4 Color White Ivory Ivory White Black Black Gray Density g/cm3 ≥3.60 ≥3.80 ≥3.85 ≥6.0 ≥3.21 ≥4.00 3.22 Water absorption % 0 0 0 0 0 0 0 Hardness HV 1500 1700 1700 1300 2500 800 Flexural strength Mpa ≥320 ≥338 ≥379 1200 550 158 650 Compressive strength Mpa ≥2000 ≥2240 ≥2240 ≥1990 ≥3306 --- ≥2200 Max. service temperature

(Non-loading) ℃ 1550 1600 1675 850 1600 1000 1200 Thermal conductivity W/(m.K) 24 29 30 2.5 150 5 25 Volume

resistivity Ω.cm > 10^14 > 10^14 > 10^14 > 10^11 10^5 10^12 > 10^14 Insulation strength kV/mm 18 18 19 17 --- 3.93 16 Dielectric constant - 9.5 9.5 9.7 29 --- 95 8.2

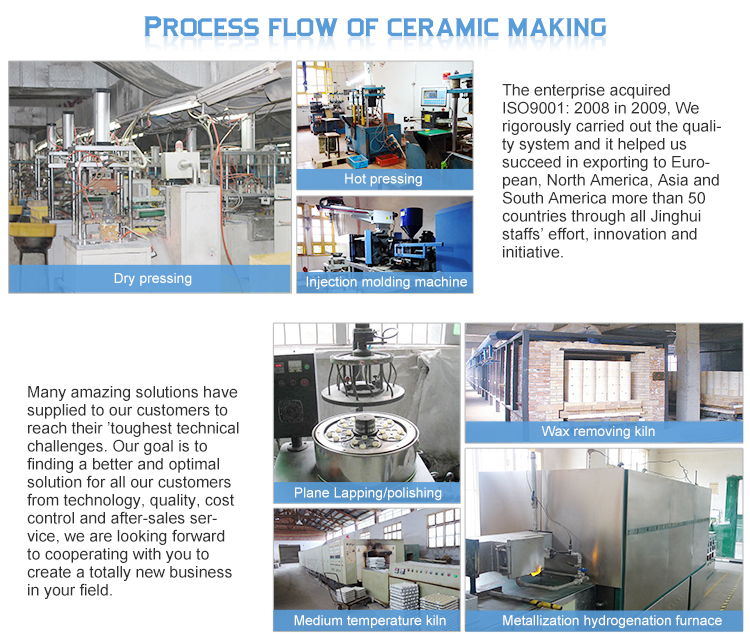

We have in-housing comprehensive manufacturing types of equipment, including forming, sintering,

CNC machining,precision grinding, laser cutting, and so on, it helps us to control the quality very well,

also it greatly benefits cost control.