Payment Type:T/T,Paypal,Western Union

Incoterm:FOB,CFR,CIF,FCA,CPT,CIP

Min. Order:500 Piece/Pieces

Transportation:Ocean,Land,Air

Port:Shenzhen Port,Hongkong Port

Model No.: Customized

Brand: Jinghui ceramics

Packaging: Export carton

Productivity: 100,000 sets/month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 500,000 sets/month

Certificate: RoHS

HS Code: 8547100000

Port: Shenzhen Port,Hongkong Port

Payment Type: T/T,Paypal,Western Union

Incoterm: FOB,CFR,CIF,FCA,CPT,CIP

1. Shaping methods: tape casting, dry pressing, isostatic pressing, hot pressing and so on.

2. Material options: aluminum oxide, zirconium oxide, silicon carbide, aluminum nitride and so on

3. Typical thickness: 0.25 mm, 0.30 mm, 0.40 mm, 0.50 mm, 0.635 mm, 0.80 mm, 1.0 mm, 1.2 mm

4. Dimension capability: min. thickness to be 0.15 mm, max. length and width to be 400 mm x 300 mm

5. Dimensional tolerance : thickness ± 0.05 mm, length ± 0.20 mm, width ± 0.20 mm

6. Surface treatment: polishing to mirror - like surface, metallizing for ceramic to metal bonding

7. Secondary process : laser cutting, fine grinding, high precision CNC machining and so on

1. High thermal conductivity, up to 25 W/m.k at room temperature and low coefficient of thermal expansion

2. Good thermal shock resistance, greater than 220 T(℃) and refractory with high - temperature resistance

3. Good surface roughness, flatness to be 0.05 mm and very smooth texture with super tiny grain size

4. High dielectric strength, high electrical resistivity, low dielectric constant and dielectric loss.

5. Laser cutting or precision machining cutting makes tight tolerance for precision fitting easily

6. More quicker heat dissipation than cooper and aluminum metal materials and increase the service life

7. Anti-aging, resistance to oxidization and free of rusty forever, also chemical stability to various harsh conditions

8. Low density, over 3.65 g /cm3, with light weight, it's benefit to design the device more lighter.

We have been producing alumina (Al2O3) ceramic substrates for over 15 years under rigorous quality control with carefully selected high purity ceramic materials that ensure stable and consistent quality and excellent properties.

These alumina substrates have extraordinary properties of electrical insulation, thermal conductivity, breaking strength and high-temperature resistance. Furthermore, one of the unique properties is its surface roughness. We can provide the Ceramic Substrate which is excellent in adhesion with a thin film and thick film metallization due to fine particles.

The main forming method we use is tape-casting, Isostatic pressing. We are dealing with a variety of selection of thickness from 0.15 mm to 20 mm, whatever, it's prototyping needs, or mass production for cost down. We could offer you an ideal solution.

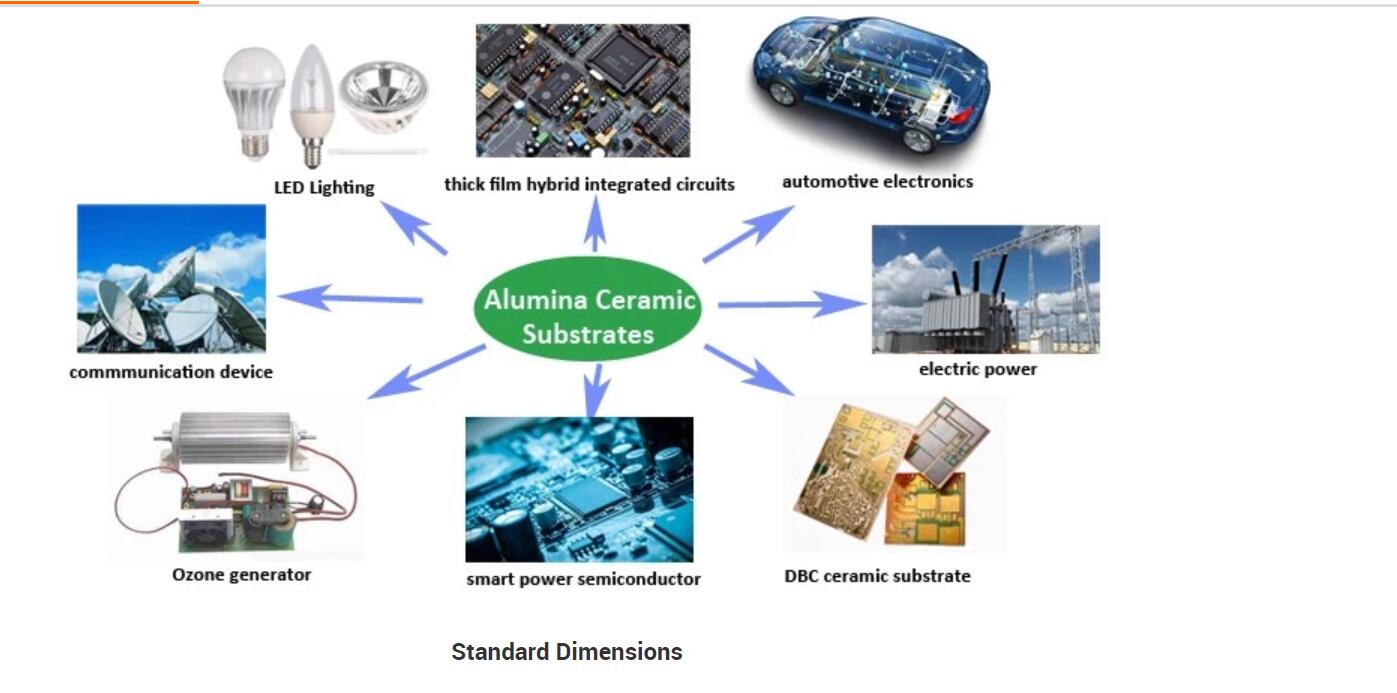

Alumina ceramic substrates are widely used in power modules, LED lighting, power semiconductor, automotive electronics, DBC ceramic substrate

Remark:

1. All big ceramic alumina substrate in above list can be cut to small size sheet, small size plate.

2. Some of above alumina ceramic substrates are made of 96% purity aluminium oxide, or 99%.

3. Other long-side and thickness can be customized, max. size is up to be 400 mm, min. thickness is small to be 0.15 mm.

★ 10+ Years of manufacturing experience in OEM, ODM and professional teams ★ Powerful R&D, mass production capability

★ In-house comprehensive manufacturing equipment from forming to machining★ Rigorous quality control system and processes

★ Surpassing pre-sales,sales & after-sales service, flexible and on-time delivery★ Abide all orders as the first priority

Q 1. Are you a factory or trading company?

A: We are a manufacturer who is dedicated to producing technical ceramic parts over 15 years of OEM, ODM

Q 2: Do you send a sample to check quality?

A: Sure, the standard design/size samples will be free and freight collect.

If it's customized alumina substrates in thickness, we will charge you sample charges with low -level MOQ.

Q 3: How long will you ship it?

A: If the products are in storage, we'll ship within 3 working days.

For special sizes or non-standard ceramic substrate, the regular lead time will be 2 weeks after order confirmed.

Q 4: Are available to manufacture ceramic substrate in different materials

A: Yes, we also produce silicon nitride substrate, nitride aluminium oxide ceramic substrates beside Alumina Ceramic Substrate.

Q 5: How do you ensure quality?

A: We have seasoned quality control system, including IQC, IPQC, QA, OQC. Also we introduced CPK, AQL in the line.

Q 6: What other products are you dealing with?

A: Besides ceramic substrates, we focus on a variety of refractory Metalized Ceramics, Ceramic Tubes, Ceramic Rods, Ceramic Grinding Burr.