Payment Type:T/T,Paypal,Money Gram,Western Union

Incoterm:FOB,CIF,FCA

Min. Order:1000 Set/Sets

Transportation:Ocean,Land,Air

Port:Shenzhen,Hongkong,Shanghai

$1.21000-9999Set/Sets

$0.9510000-49999Set/Sets

$0.85≥50000Set/Sets

Model No.: Standard or custom-made

Brand: Jinghui ceramics

Place Of Origin: China

Species: Ceramic Parts

Application: Industrial Ceramic

Material: Alumina Ceramic

Processing Service: Moulding

Secondary Process: Precision Grinding, Cnc Machining

Shaping Method: Dry Pressed, Hot Pressed

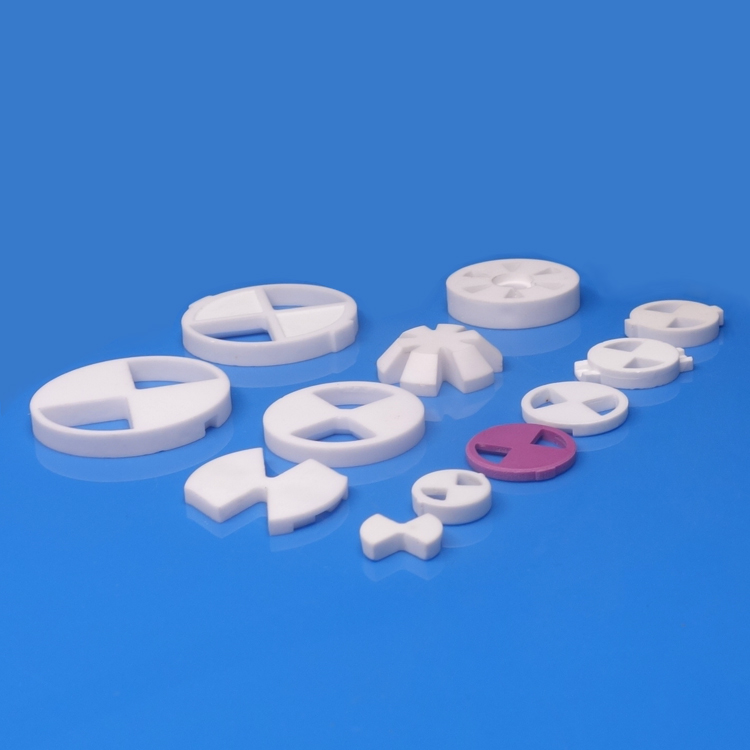

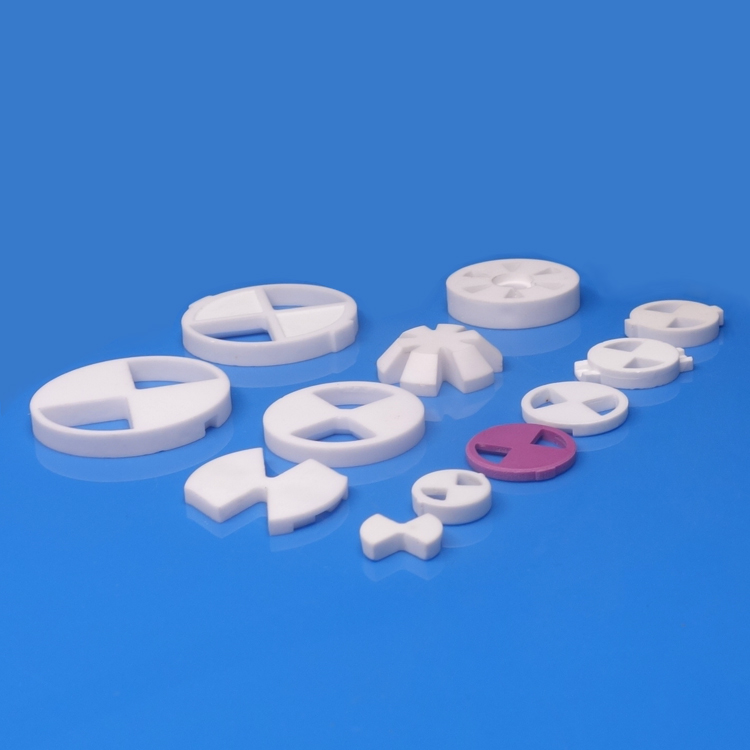

Product Name: Alumina Ceramic Seal Discs

Material Options: Alumina, Zirconia, Silicon Carbide

Available Max. Diameter: Outer Diameter Up To 300mm

Surface Finish: Diamond Plished To Be Ra0.2

Features: Super Abrasive With Long Service Life

Application: Ceramic Seal Disc For Water, Gas, Oil Valve

Packaging: Export carton

Productivity: 5,000,000 sets/month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 10,000,000 sets/month

Certificate: RoHS

HS Code: 8547100000

Port: Shenzhen,Hongkong,Shanghai

Payment Type: T/T,Paypal,Money Gram,Western Union

Incoterm: FOB,CIF,FCA

With our veteran manufacturing experience and skilled engineering technology advantage for advanced ceramic components, all ceramic seal discs we supplied offer an extraordinary sliding surface, diamond-like hardness. They also own exceptional chemical resistance against acids and alkaline environments due to the special characteristics of technical ceramics. And these properties lasts to ensure a superior long service lifetime.

Besides, Alumina Ceramic seal discs, as well as we manufacture alumina ceramic sea ring, zirconia ceramic valve seat and balls, and silicon carbide valve disks. All of the ceramic seal components we supplied could control the amount of fluid, gas very well even if after a few millions of cycles. You will not find any leaking after so long working time.

Why alumina ceramic seal discs?

1. Much better hardness and compressive strength than traditional seal parts;

2. Excellent wear and abrasive resistance with a longer service lifetime;

3. Great corrosion resistance to acids, alkalis in water, gas and oil fluids;

4. More ideal working surface with diamond polished to be Ra0.2;

5. Super low friction coefficient with self-lubrication to prolong the life-span.

6. More cost-effective in high volume needs than stainless steel seal parts

The applications of ceramic seal discs:

Shower flow valves, Single lever mixer,Pneumatic valve friction discs,Automotive water pumps,Medical control devices,General domestic and industrial pumps

1. We have in-house art-of-the-state comprehensive manufacturing equipment, including grinding & mixing machines for material preparation, selection of shaping machines, sintering furnace, fine grinding machines, CNC machines, surface treatment production line ( polishing, glazing, metalizing) and electroplating production line.

2. We strictly perform the management quality system per ISO9001: 2015 and all departments of IQC, IPQC, OQC have veteran and professional staffs. Every pieces flow to the customers have been inspected rigorously.

3. Focus on cost down, we pay special attention to every details beginning from purchasing material to shipping and thinking of how to reduce the cost prior to ensuring the quality.

Q 1. Are you a factory or trading company?

A: We are a direct manufacturer with 12 years experience of OEM, ODM. You are welcome to visit our factory.

Q 2: DO you send a sample to check the quality?

A: Sure, the standard samples with stock are free and freight collect.

We also accept trial/sample order for customized ceramic seal discs to support prototyping needs.

Q 3: Are you available to provide customized products?

A: Yes, we support custom-made ceramic seal discs as per different materials, dimensions, and designs.

Q 4: How do you ensure quality before shipping?

A: Sampling inspection each batch is must before shipping. The KPI value and QAL standard are perform in the process strictly.

Q 5: What other products are you dealing with?

A: We not only produce ceramic seal discs, but not manufacture alumina Metallized ceramics, Ceramic Grinding Burr, Textile Ceramics and so on.